In harsh industrial scenarios such as high-temperature and strong corrosion environments, equipment sealing faces enormous challenges. Teflon seals produced by Mascot Sealing have become the ideal choice to tackle these challenges with their excellent performance. Let's deeply analyze their "hardcore strengths".

Teflon seals can operate stably within the temperature range of -200°C to +260°C. Whether in the ultra-low temperature environment of liquid nitrogen freezing equipment or the high-temperature working conditions of steam pipelines, they maintain consistent sealing performance without degradation, ensuring stable equipment operation.

Resistant to strong acids (e.g., sulfuric acid, aqua regia), strong alkalis (e.g., sodium hydroxide), and various organic solvents, they are known as "chemical medium insulators". In complex chemical environments, they retain structural integrity and sealing effectiveness, effectively preventing medium leakage.

With an extremely low friction coefficient (only 0.04), Teflon seals require no additional lubrication, making them ideal for high-speed rotating equipment such as pump shafts and compressors. This reduces frictional wear and extends equipment service life.

In chemical reactors handling strong acid-base solutions, ordinary seals are prone to cracking and leakage. Mascot Teflon seals achieve efficient sealing with their superior performance. After a certain chemical plant switched to our Teflon seals, equipment maintenance costs decreased by 60%, significantly improving production efficiency and safety.

Mascot Teflon seals are non-toxic, non-adhesive to media, and comply with FDA hygiene standards, widely used in sterile filling lines, pharmaceutical reaction tanks, and other equipment. You can intuitively observe their professional application in the food & pharmaceutical field through the installation close-ups of food-grade Teflon seals in milk pipelines displayed on our official website.

Facing the extreme environments of aerospace, our Teflon seals demonstrate strong adaptability, with radiation resistance and vacuum tolerance. They are commonly used in key components such as rocket fuel pipelines and satellite sealing systems, contributing to the national aerospace industry.

The quality of Teflon seals in the market varies widely. Inferior products may contain recycled materials, leading to reduced temperature resistance and easy aging. When purchasing, refer to the following identification methods:

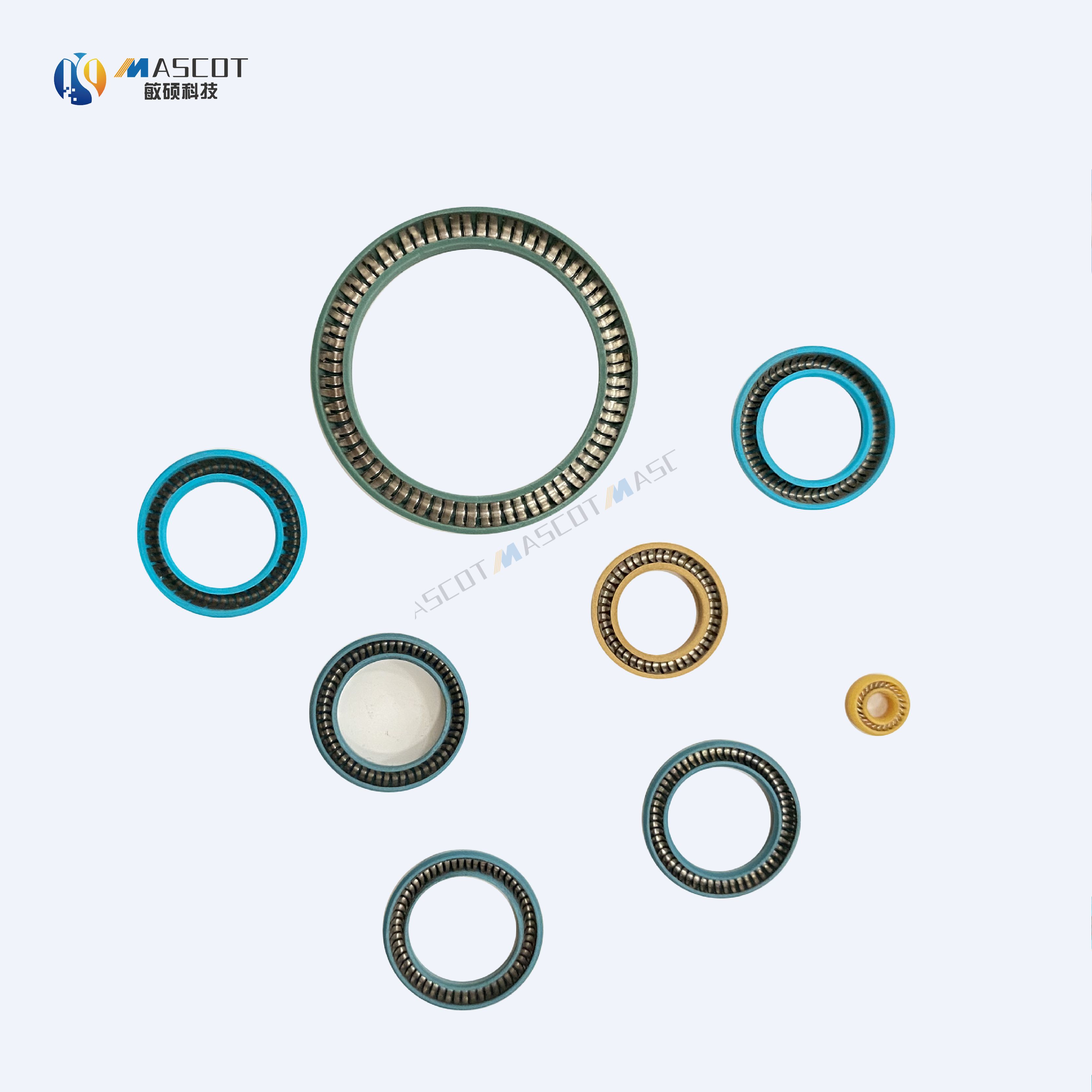

- Visual Inspection: High-quality Mascot Teflon seals feature a smooth surface without impurities, uniform color, and exquisite craftsmanship.

- Certificate Verification: We provide material testing reports issued by professional third-party institutions, including temperature resistance tests and corrosion resistance certifications, to ensure product quality.

- Toughness Test: Gently bend the Mascot Teflon seal—it should rebound quickly without white creases, demonstrating good toughness.

Mascot Sealing adopts advanced compression molding technology, and our products are manufactured in strict compliance with and exceeding industry standards, providing you with more reliable sealing solutions. Meanwhile, we support customization of special-shaped parts: our professional team can carefully design lip structures and precisely control cross-sectional dimensions according to different working conditions to meet your personalized needs.

If your equipment is troubled by leakage, please visit Mascot Sealing's official website to leave a message with your working conditions. We will provide you with professional sealing solutions!