Material Introduction

Material Introduction

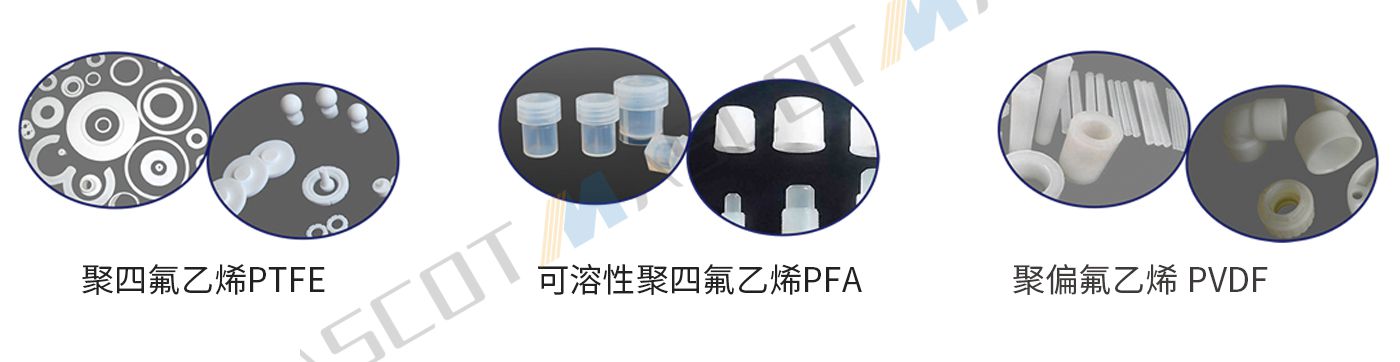

PTFE

PTFE is a kind of high temperature resistant fluoroplastics. One of the most remarkable characteristics of this material is that it is not sticky. Under the action of pressure, the PTFE filled plastic will form a thin PTFE sliding film on the surface of the mating surface. The addition of PTFE can reduce the wear and friction coefficient and improve the heat resistance.

PFA

The long-term use temperature is -80 - +260 ℃, which has excellent chemical corrosion resistance, corrosion resistance for all chemicals, low friction coefficient, good electrical performance, and no influence of temperature on electrical insulation. It is suitable for making corrosion-resistant parts, wear-resistant parts, seals, insulation parts, medical equipment parts, high temperature wires, cable insulation, anti-corrosion equipment, sealing materials, pump valve bushing and chemical containers.

PVDF

Excellent chemical resistance, good electrical, high temperature resistance, toughness and mechanical properties; It can be melt processed like thermoplastic material, non-toxic and flame retardant.

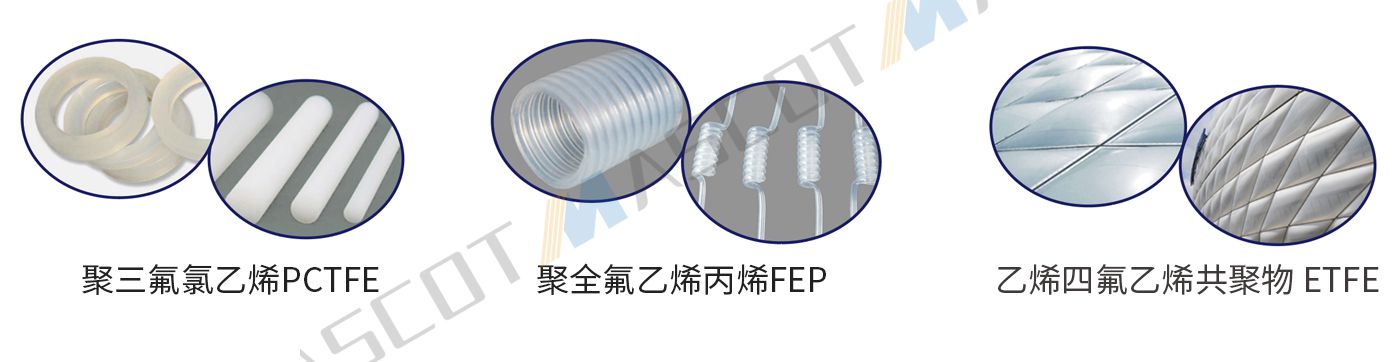

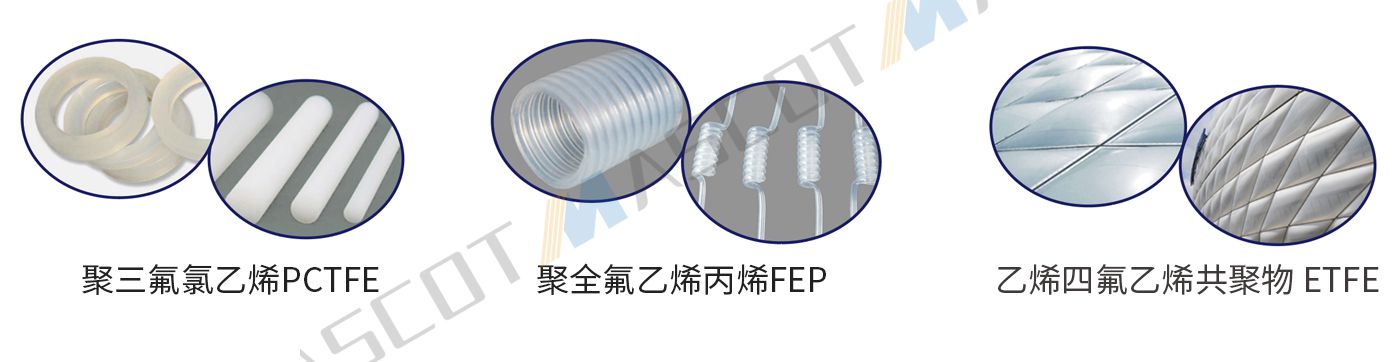

PCTFE

Excellent low temperature resistance, no brittle crack and creep in liquid nitrogen, liquid oxygen and liquefied natural gas. It is inert to most active chemicals at room temperature, has excellent gas barrier ability, almost impermeable, low permeability, low water absorption, good transparency, mechanical properties increase with the increase of crystallinity, excellent insulation and weather resistance, and can be used at - 196 ~ 125 ℃ for a long time.

FEP

FEP is a kind of soft plastic. Its tensile strength, wear resistance and creep resistance are lower than those of many engineering plastics. It has chemical inertness, low dielectric constant, non ignition, and can prevent flame diffusion. It has excellent weather resistance and low friction coefficient. It can be used from low temperature to 392 ℃. It is mainly used for making lining of pipe and chemical equipment, surface layer of roller and various wires and cables, such as aircraft hook line, booster cable, alarm cable, flat cable and oil well logging cable.

ETFE

Good dynamic friction performance, excellent chemical resistance and mechanical properties, flame retardant, meet the requirements of food processing.

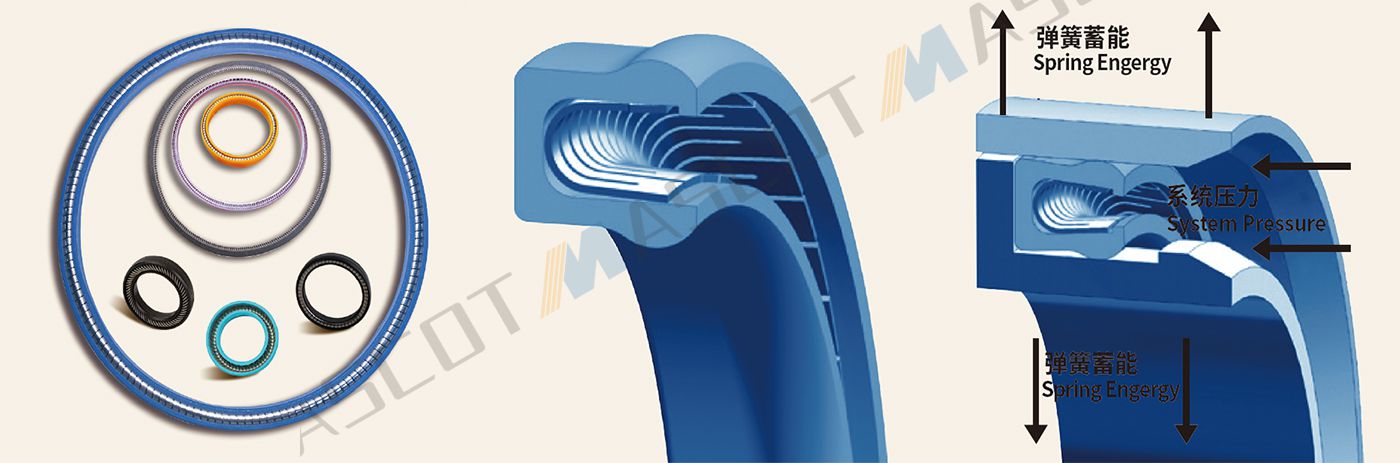

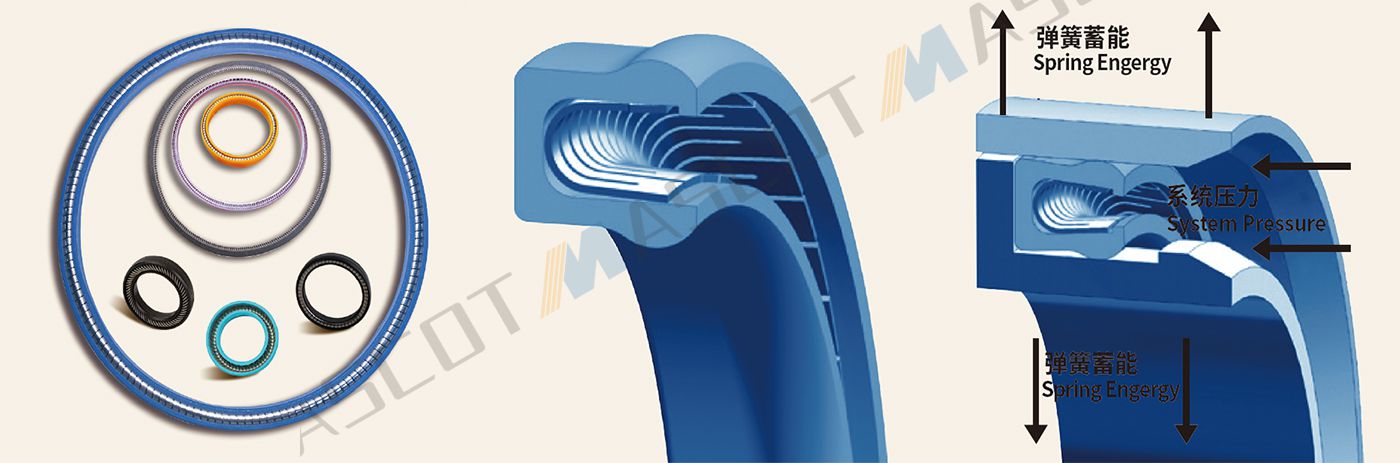

The jacket of the seal ring is supported by a V-shaped spring with corrosion resistance, and the spring cavity filled with silicone can be used for food processing and in-situ cleaning applications. Our products are suitable for applications with ultra-low friction, chemical compatibility and extreme temperature requirements. It has been widely used in aerospace, automotive and energy fields, including jet engine, helicopter rotor, oil field equipment and fuel pump.

Minshuo spring energy storage seal ring is a spring driven pressure auxiliary sealing device with PTFE jacket, in which a corrosion-resistant metal energy storage spring is specially equipped. When the minshuo seal ring is installed in the seal groove, the spring is pressed to make the jacket lip close to the seal groove, thus forming a seal. The spring provides permanent elastic force for the sealing jacket, and makes up for material wear and offset or eccentricity of matching parts. The system pressure also assists in the seal jacket energy storage. Through the spring force assisted by the system pressure, the effective sealing can be realized no matter in high or low pressure.

Minshuo jacket is made of polytetrafluoroethylene, filled polytetrafluoroethylene and other high-function polymer materials by precision turning. Minshuo sealing ring with PTFE jacket is suitable from low temperature to 572 deg; F(300° C) In addition to soluble alkali metals, high temperature fluorine gas and chlorine trifluoride (clf3), it hardly reacts with any chemical reagent.

Minshuo products have a variety of energy storage springs to choose from, each spring has different characteristics to meet the special requirements. The spring load can meet the extremely harsh low friction requirements in dynamic applications and the high load requirements usually required for cryogenic seals. Springs are made of corrosion resistant metals such as 300 series and 17-7 pH stainless steel. Minshuo products with metal spring have unlimited storage life, and there is no aging problem of rubber sealing ring. The geometry of minshuo seal ring installed on the seal groove can also avoid the common torsion or screw failure of O-ring

Static seal and dynamic seal:

The two basic types of seal applications are static seal and dynamic seal.

For the static seal, there is basically no relative movement between the seal ring and the matching parts. For example, bolted flanges are the most common example.

For dynamic seal, the two sealing surfaces have relative movement. Typical examples include the sealing of piston rod and piston in hydraulic cylinder. Dynamic seal includes two forms of motion: reciprocating motion (linear motion) and rotary motion (including swing). Radial seals (rod and piston seals) are available for these applications. Sometimes static seal and dynamic seal will be used together. Please refer to the following application suggestions or contact our technical support team

Seal ring features:

1. It can be used for reciprocating and rotary motion

2. Small friction coefficient, wear resistance and stable size

3. Strong corrosion resistance and good dimensional stability

4. It will not pollute food, medicine and pharmaceutical liquid

5. It can adapt to most fluids and chemicals

6. It will not crawl even if it is controlled precisely

7. It can withstand sharp temperature changes8.It can be disinfected9.Unlimited storage