-

NBR (Nitrile Rubber): Good Oil Resistance

As one of the commonly used sealing materials, NBR is widely applied for its good resistance to petroleum-based oils, fuels, and lubricants, along with decent wear resistance and high cost-effectiveness. However, its weaknesses include poor resistance to ozone and UV (prone to aging and cracking) and limited resistance to polar solvents.

Commonly used in: Automotive fuel systems, hydraulic equipment, and various oil pressure pipelines. -

FKM (Fluoroelastomer): Suitable for High-Temperature Chemical Environments

FKM is a common material for harsh environments. It offers relatively good high-temperature resistance, chemical corrosion resistance (resistant to oils, acids, and many solvents), and good anti-aging capabilities. Its drawbacks are its relatively high cost and room for improvement in the low-temperature elasticity of standard formulations.

Commonly used in: Automotive engine oil seals, chemical pumps and valves, and aerospace applications. -

EPDM (Ethylene Propylene Diene Monomer): Suitable for Moisture Environments

EPDM exhibits good resistance to hot water, steam, cold climates, and ozone, while also being compatible with brake fluids (DOT series) and refrigerants (e.g., R134a). However, it has a significant weakness: it is not resistant to mineral oils and fuels.

Commonly used in: Automotive cooling systems, door seals, household appliances (e.g., washing machines, water heaters), and HVAC systems. -

SIL (Silicone Rubber): A Choice for Wide Temperature Ranges

Silicone rubber offers a relatively wide temperature range and good flexibility, along with non-toxic and odorless properties that meet food and medical-grade requirements. However, its mechanical strength is relatively low, wear resistance is limited, and it is not oil-resistant.

Commonly used in: Food and medical equipment, high-temperature baking equipment, and applications requiring physiological inertness. -

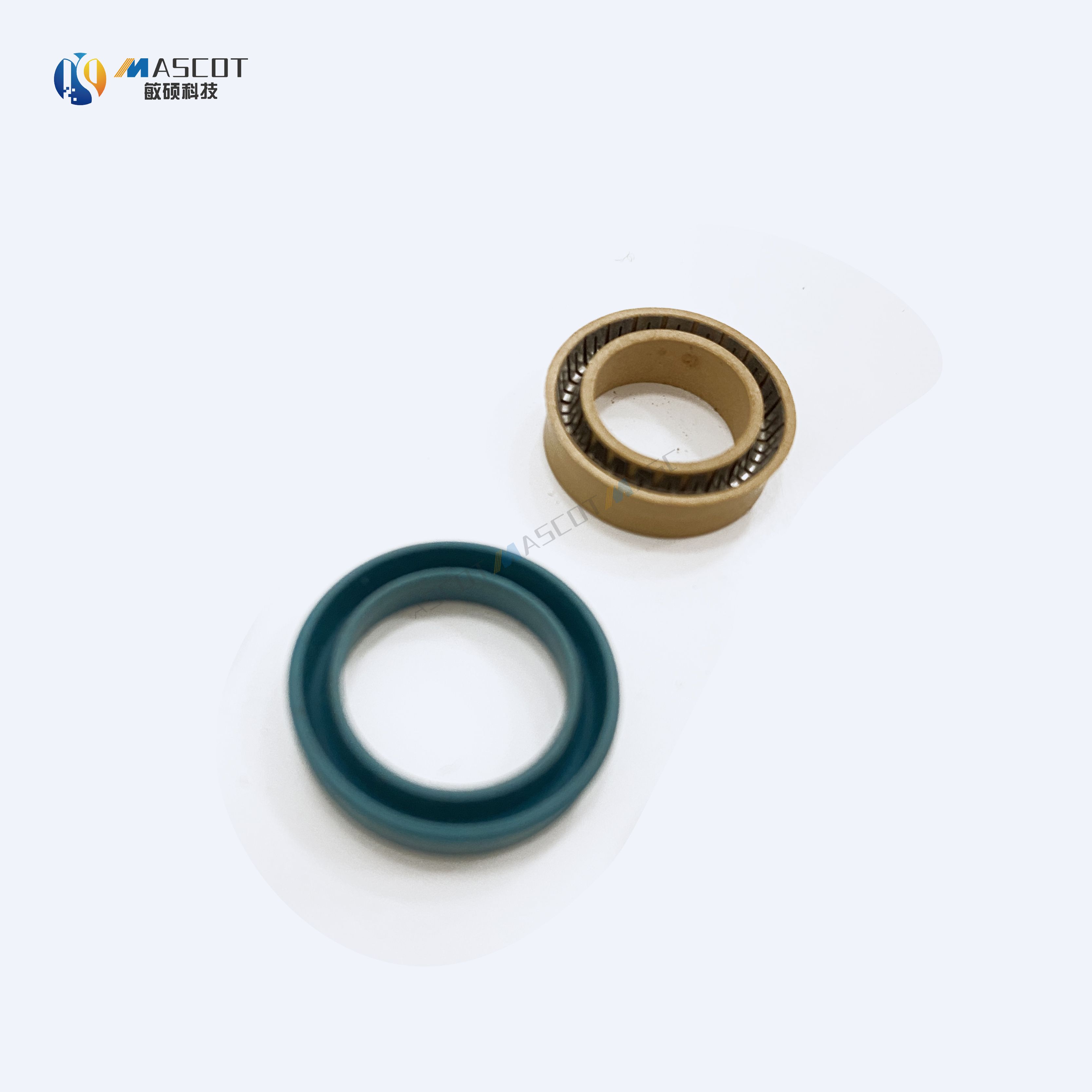

PTFE (Polytetrafluoroethylene): Good Chemical Stability

PTFE is valued for its ability to resist a wide range of chemicals, low friction coefficient (self-lubricating), and relatively broad temperature range. It often requires modification or combination with elastomers to compensate for its lack of elasticity and tendency to cold flow.

Commonly used in: Strong acid and alkali environments, high-purity applications (e.g., semiconductors, food, and pharmaceuticals) for pump and valve sealing. -

PEEK (Polyether Ether Ketone): High-Performance Engineering Plastic

As a specialty engineering plastic, PEEK is used to manufacture high-performance sealing components (such as Mascot Spring-Energized Seals and gaskets) due to its relatively high mechanical strength, good high-temperature resistance, creep resistance, and chemical resistance. It maintains relatively stable shape under continuous high temperature and pressure, with better extrusion resistance than ordinary rubber. Its drawbacks are its higher cost and the need for precision machining.

Commonly used in: High-pressure hydraulic systems, deep-well drilling equipment, high-performance engines, and applications requiring wear resistance and long service life.

After understanding the characteristics of various sealing ring materials, selecting the most suitable sealing solution for your equipment becomes particularly important. This not only affects operational efficiency but also directly impacts production safety and cost control. As a professional brand in the sealing industry, Mascot Sealing offers comprehensive material selection guidance and high-quality sealing products, backed by years of R&D experience and technical expertise.