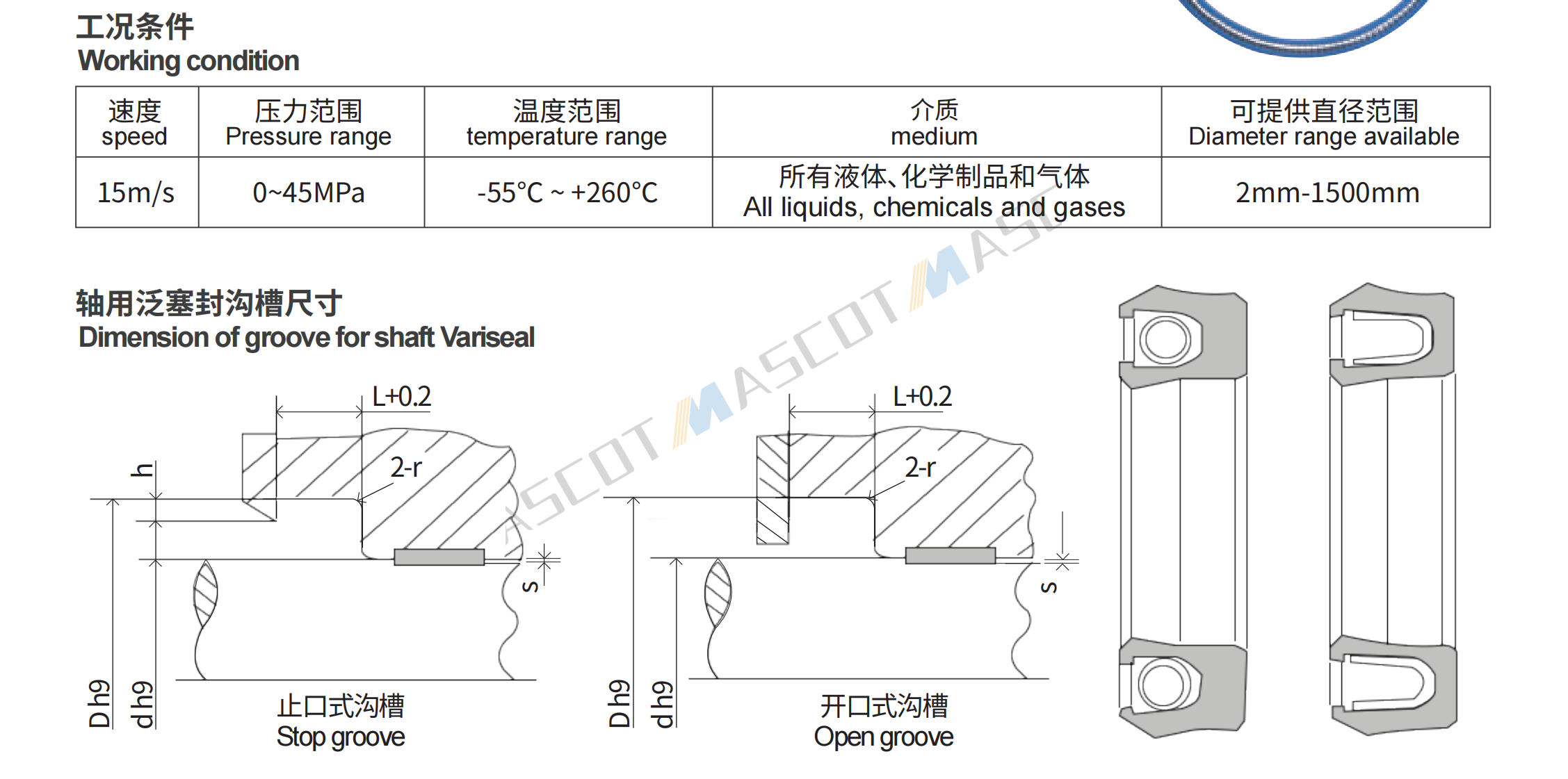

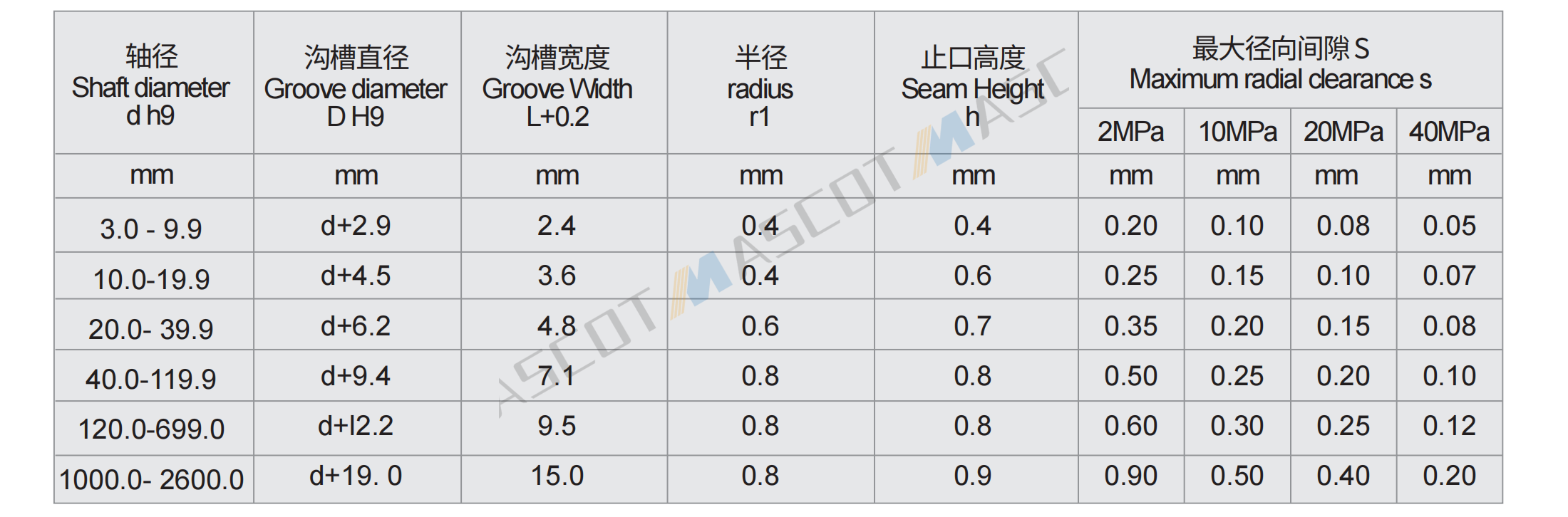

Rod variseals focus on inner - circumference sealing and are specifically designed for reciprocating motion scenarios of shafts. No matter how harsh the working conditions are, such as high - temperature (-55℃ ~ +260℃), high - pressure (0 - 45MPa) environments, or contact with complex media (various liquids, chemicals, and gases), they can function stably.

Structurally, rod variseals come with stop - type and open - type groove designs (along with clear dimension parameter tables, covering key data such as shaft diameter and groove diameter). They are adaptable to a diameter range of 2mm - 1500mm, meeting the needs of different shaft - type devices. In equipment like valves, pumps, and separators, they eliminate the crawling phenomenon, ensure the sealing effect, and make the operation of the equipment more stable and reliable. They are powerful “guardians” for shaft sealing.

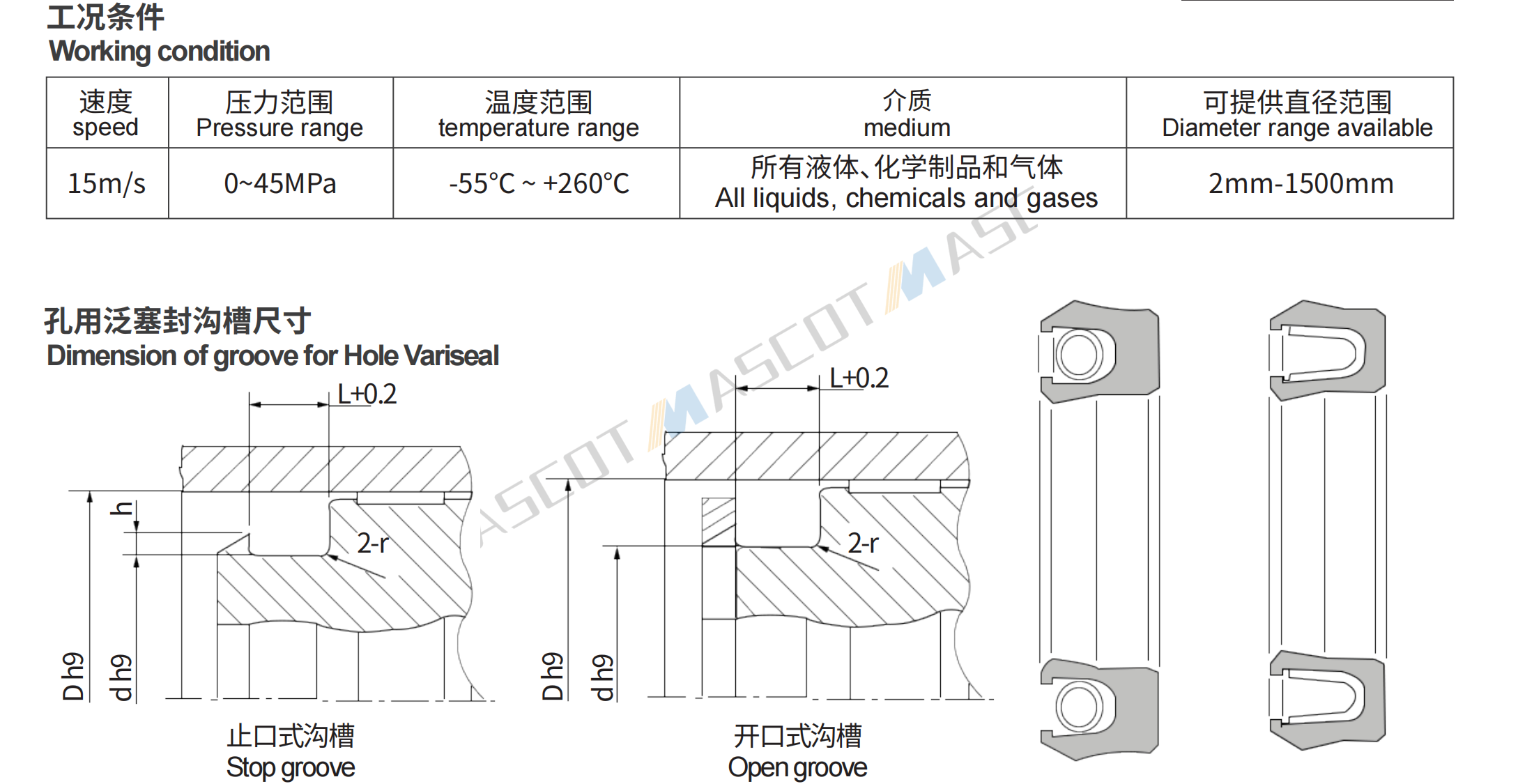

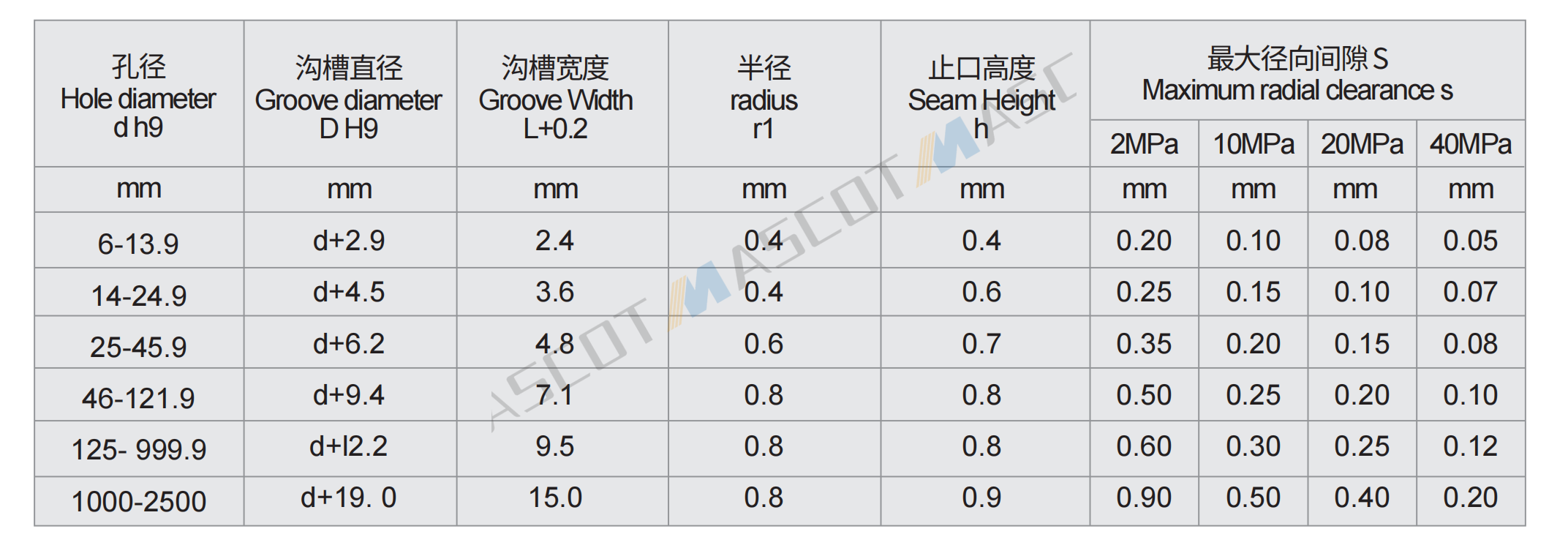

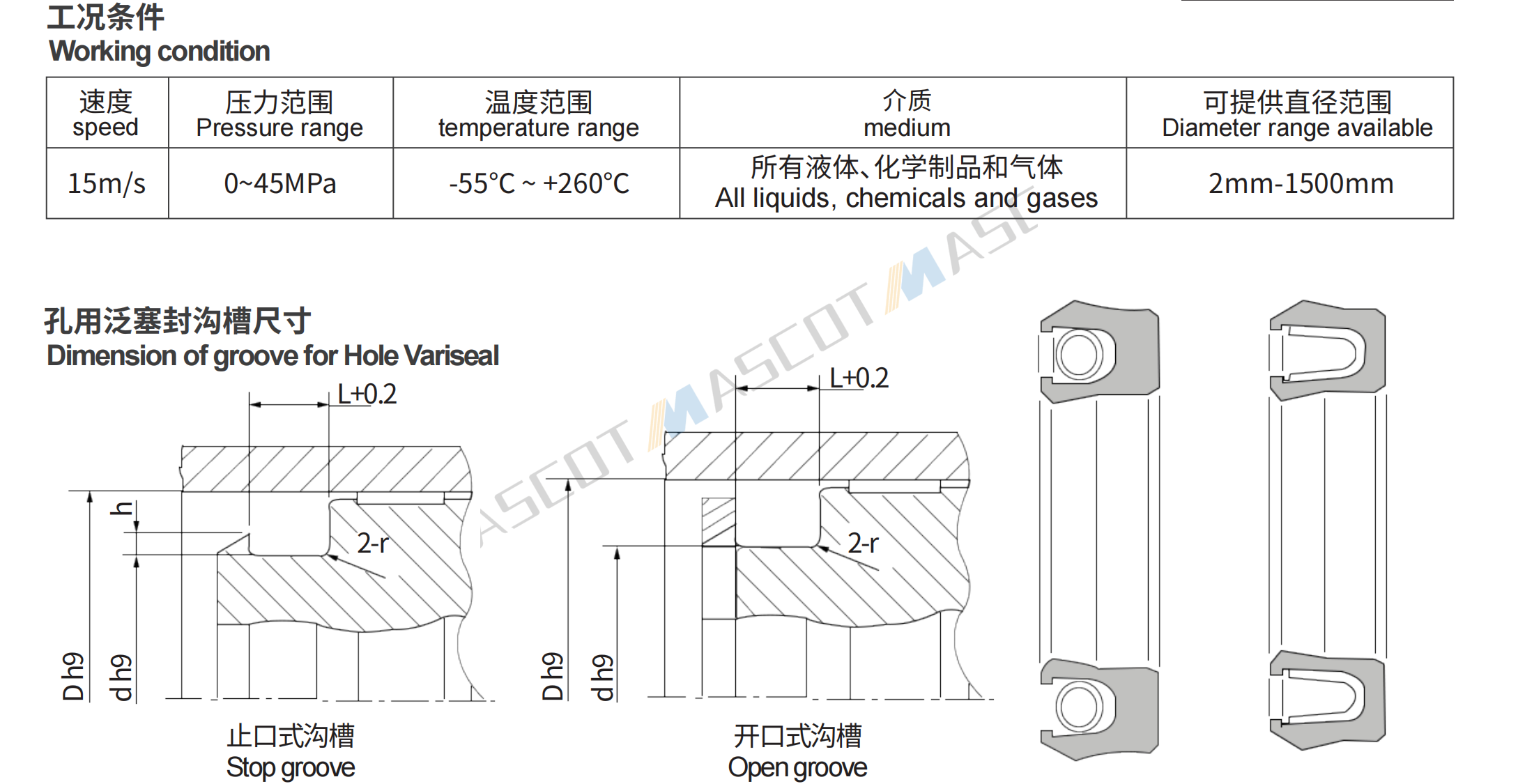

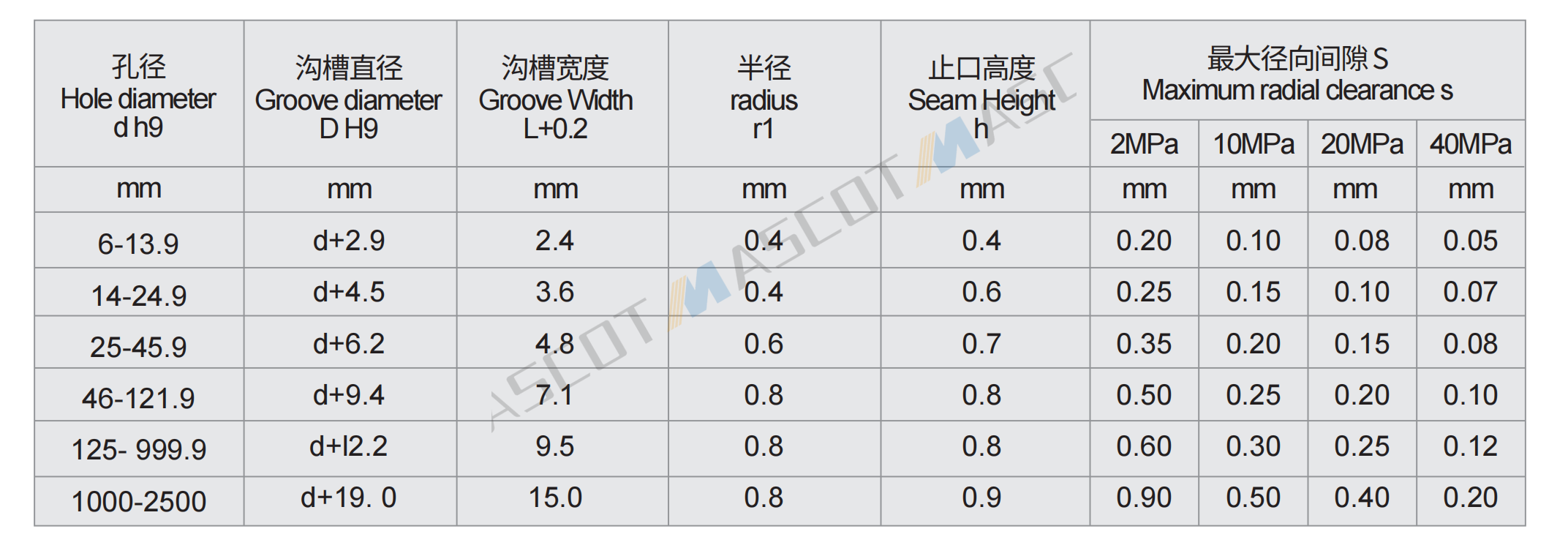

Piston variseals also serve the reciprocating motion of inner - circumference sealing and build a sealing barrier for bore - type devices. When facing harsh working conditions and special media, they demonstrate excellent adaptability. Their temperature, pressure, and media compatibility are consistent with those of rod variseals, providing escort for the stable operation of bore - type components.

Their structure includes stop - type and open - type grooves (corresponding to detailed dimension parameters, covering indicators such as bore diameter and groove diameter). The adaptable diameter range is 2mm - 1500mm, covering various specifications of bore - type devices. When applied in scenarios such as valves, pumps, and brakes, relying on characteristics like no crawling and chemical resistance, they become solid “shields” for bore sealing, safeguarding the integrity of device sealing.

Mascot Technology’s rod and piston variseals, with their precise structural design and wide range of working condition adaptability, provide reliable sealing solutions for industrial equipment. From the detailed data in the parameter tables to the stable performance in practical applications, their technical strength is evident. Whether facing challenges of complex working conditions or the adaptation to special media, choosing Mascot variseals is like adding an “insurance” for device sealing, facilitating the smooth and continuous progress of industrial production.

If you want to know more about the selection and application details of variseals, feel free to keep following echnology and explore more possibilities in industrial sealing!