In industrial design and precision machinery, springs are among the most common yet critical components. In recent years, an elastic element known as the "opposed wave spring" has gradually captured the attention of engineers. With its unique structure and exceptional performance, it has become an ideal choice to replace traditional coil springs in many applications.

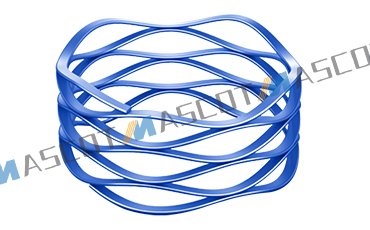

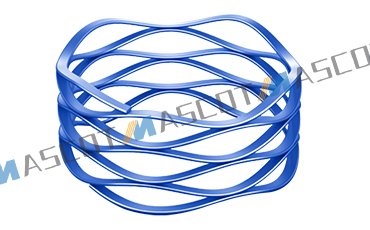

As the name suggests, the Mascot opposed wave spring is a spring structure formed by periodically arranged wave peaks and valleys, symmetrically stacked in an opposed manner. Its most notable feature is its outstanding performance under conditions of small to medium load and long travel. Compared to ordinary cylindrical coil springs, the Mascot opposed wave spring can save at least half the space while bearing similar loads, significantly improving spatial efficiency.

Why is it so popular in compact applications? The answer lies in its structural efficiency. Traditional coil springs rely on elastic deformation between coils to store energy, whereas the opposed wave spring achieves elastic function through the compression of wave layers. The deformation is concentrated in the wave peak and valley areas, allowing it to occupy minimal axial space while still providing sufficient elastic force and travel. This characteristic makes it highly suitable for applications where axial space is limited, such as precision instruments, small valves, automotive clutches, robotic joints, or medical devices.

In addition to saving space, the Mascot opposed wave spring helps reduce the overall volume of equipment, lowering material and manufacturing costs. A smaller volume means lighter and more compact product designs, aligning with the modern industry's pursuit of efficiency and energy savings.

Furthermore, this type of spring offers excellent design flexibility. By adjusting material thickness, width, or even adopting two or three overlapping layers, springs with different stiffness and load requirements can be easily customized to meet various application needs, ranging from a few newtons to several thousand newtons, demonstrating strong engineering adaptability.

For these reasons, the Mascot opposed wave spring is gradually replacing traditional coil springs in many fields. It not only enhances mechanical system performance but also embodies the modern manufacturing philosophy of "achieving more with less"—using fewer materials to deliver stronger functionality and smarter structures to create greater possibilities. In the future, with the continuous development of micro-electromechanical systems, automation control, and high-end equipment, the application prospects of opposed wave springs will become even broader. This small yet powerful component is quietly supporting technological progress and innovation.

If you are struggling with limited device space or finding it difficult to optimize designs due to the bulkiness of traditional springs, Mascot Opposed Wave Springs are your ideal solution. We specialize in the field of wave springs, offering a wide range of high-quality products in various specifications and materials, along with professional customization services to ensure your project achieves the optimal balance of performance, cost, and space.

Contact the Mascot Technology technical team today for free selection advice and start a new chapter in efficient, compact design!