Wave springs, referred to as wave springs for short, are precision elastic components with multiple peaks and valleys processed on thin metal rings. Leveraging their flat-wire structure, they offer a core advantage of 50% space savings, making them widely used in compact scenarios that require small load and deformation, as well as axial preload. Relying on material optimization and precision manufacturing processes, Mascot deeply integrates the reliability, applicability, and durability of wave springs into various structural designs, accurately meeting the diverse needs of the high-end manufacturing field.

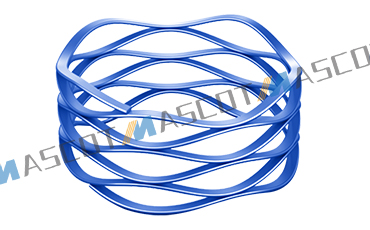

Regular opposed wave springs adopt a multi-layer design with peaks overlapping valleys. They do not require support coils at both ends, have a total number of layers of no less than 2, and the number of waves per layer is mostly non-integer, such as 2.5 or 3.5. The upper and lower layers of these wave springs are in direct contact through peaks and valleys, and the number of active coils is consistent with the total number of coils. In terms of performance, they store energy through the compression of opposed waves, providing more stable axial force in the same space. After Mascot's heat treatment process, the tensile strength of the material is significantly improved, making them suitable for medium-load scenarios. In practical applications, they are commonly used in automotive clutch pressure adjustment, precision valve preloading devices, and are especially suitable for transmission systems with strict installation height restrictions.

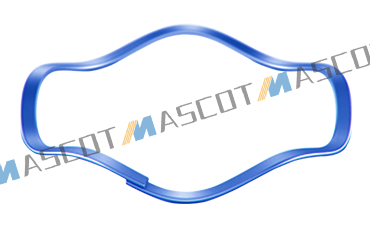

Based on regular opposed wave springs, flat-end opposed wave springs are added with flat coils at both ends as support structures. They also have a total number of layers of no less than 2, with the number of waves of active coils covering common specifications such as 2.5 and 3.5, and the number of active coils is 2 less than the total number of coils. The flat-coil support design enables the wave spring to achieve 360° uniform contact, increasing the load distribution accuracy by 15% while preventing peaks from sinking into the mounting hole. Through strict dimensional precision control, Mascot keeps the fitting clearance of these wave springs within ±0.1mm, making them widely used in high-speed rotating components with high requirements for uniform force, such as motor bearing end caps and medical equipment spindles.

Laminated wave springs are composed of multiple layers of wave washers stacked in parallel. They have a total number of layers of no less than 2, and the number of waves of active coils is mostly integer, such as 3 or 4. Load is transmitted between layers through full contact of upper and lower surfaces. This stacked structure allows the load capacity of the wave spring to increase linearly with the number of layers. Through optimized design, Mascot makes the product's fatigue life better than industry standards, capable of withstanding working pressure above 10MPa. Currently, they are widely used in heavy-load scenarios requiring rapid response, such as spool reset in hydraulic directional valve groups and heavy machinery transmission systems.

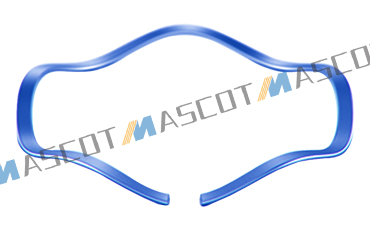

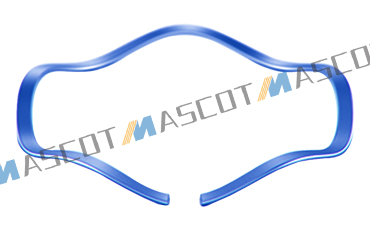

Lap-joint wave washers are single-layer unclosed structures, with their ends partially overlapping at peaks or valleys. They have no less than 3 waves and a total number of layers of only 1. The lap-joint design not only ensures structural stability but also improves assembly flexibility, allowing minor radial adjustments. They are suitable for light-load scenarios that require convenient assembly, such as preloading of electronic connector contacts and positioning devices of small instruments.

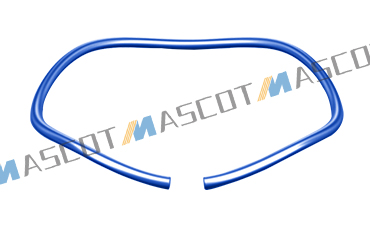

Open-end wave washers are also single-layer structures. Their rings are unclosed, with ports located at peaks or valleys and a certain gap left between the ports. They have no less than 3 waves and a total number of layers of 1. The open structure can effectively absorb dimensional errors caused by temperature changes, making the stress distribution more uniform.

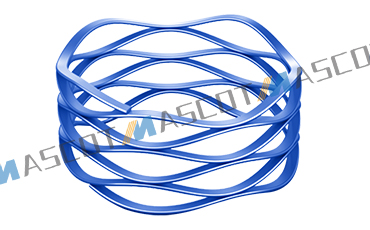

Round-wire wave springs are made of metal wires with a circular cross-section. Through precision bending and forming processes, continuous peak and valley structures are processed on the rings, and they can be designed as single-layer or multi-layer. Compared with traditional flat-wire wave springs, the round-wire material endows the product with better toughness and impact resistance, and it is less likely to have stress concentration in dynamic load scenarios. Through wire surface polishing and tempering treatment, Mascot further improves the product's corrosion resistance and fatigue limit, enabling it to maintain stable performance even under frequent expansion and contraction conditions.

For specific types of wave spring selection manuals or customized solutions, you can contact the Mascot technical team immediately. We will provide you with exclusive elastic solutions. Welcome to call: 400-008-3858!