In the field of industrial hydraulics and pneumatics, the performance of seals is crucial to the stable operation and service life of the entire system. With its unique advantages, the V-ring seal plays a key role in complex working conditions such as heavy loads and high pressures. Next, let's explore the V-ring seal in depth.

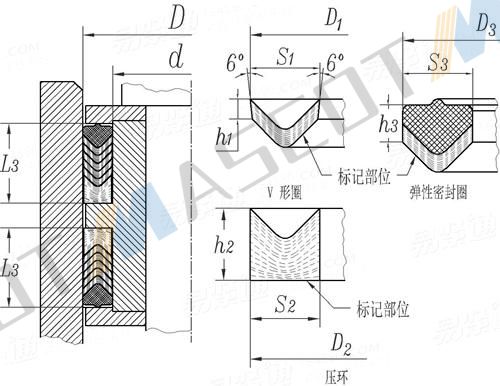

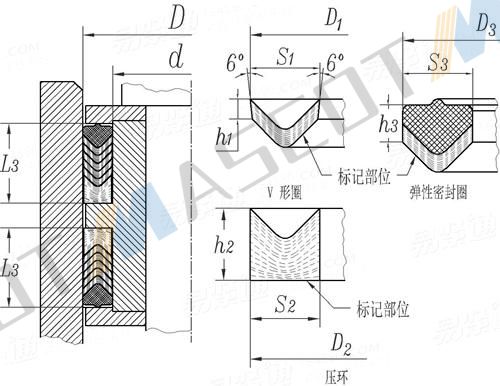

The V-ring seal has a unique structure, which also endows it with extraordinary performance. It has a "V"-shaped cross-section and is an axially acting lip seal. Unlike the common O-ring, it is usually used as an assembly. A complete V-ring sealing system includes multiple V-rings, a support ring (wear-resistant ring) and a pressure ring. This structure makes it widely applicable, not only for reciprocating motion (such as the piston rod seal of hydraulic cylinders) but also for low-speed rotation and spiral motion.

The V-ring seal achieves dynamic sealing through a dual mechanism. Firstly, initial preloading provides static protection. During installation, an axial compression force is applied to the V-ring seal assembly by means of a gland. This force causes elastic deformation of the V-ring's lips, making them expand and closely fit the sealing surface (such as the piston rod or the inner wall of the cylinder barrel). The resulting initial contact pressure can effectively achieve static sealing even when the system pressure is zero, preventing medium leakage.

Secondly, pressure adaptation realizes dynamic enhancement. When the system starts to operate, the medium pressure becomes an important driving force for sealing. Pressure acts on the back of the V-ring's lip through gaps, generating radial force that pushes the sealing lip more tightly against the sealing surface. Moreover, the higher the system pressure, the greater the contact pressure between the sealing lip and the surface, and the better the sealing effect. This characteristic makes it very suitable for medium and high-pressure working conditions.

At the same time, multi-lip coordination forms redundant protection. The superposition of multiple V-rings is like setting up multiple sealing lines of defense for the system. Even if one of the lips is slightly damaged due to impurities or wear, the remaining lips can still work normally, greatly improving the reliability and safety of the seal. The supporting ring behind can prevent the seal ring from being squeezed into the fitting gap of moving parts under high pressure, ensuring its long-term stable operation.

Based on the above characteristics, the V-ring seal has significant advantages. It has high sealing reliability, can maintain stable sealing under high pressure and impact loads with a low failure rate. It has strong pressure resistance and impact resistance; combined with the support ring, it can withstand high pressure and buffer pressure fluctuations and hydraulic shocks. It has excellent automatic wear compensation ability; after the lip is worn, it can automatically follow up radially under the action of medium pressure, extending the service life. It is adjustable and easy to maintain; when slight leakage occurs, there is no need to replace the seal or disassemble the equipment, and the sealing performance can be restored only by tightening the gland nut, reducing maintenance costs and time. By selecting different materials, it can also adapt to a variety of media, with a wide range of applications.

For this reason, the V-ring seal has become an ideal choice for many harsh scenarios. It can be seen in construction machinery (such as hydraulic cylinders of excavators, loaders, cranes, etc.), heavy metallurgical equipment (such as hydraulic systems of rolling mills, forging presses), high-pressure valves, and various reciprocating motion sealing occasions that require high safety, reliability, and maintainability. Founded in 2005, Mascot has focused on technological innovation for 20 years. It has established a team of doctors and senior engineers, developed a variety of exclusive formulas, and equipped with dozens of high-speed and efficient production equipment. Over the years, Mascot has provided sealing system solutions for well-known enterprises at home and abroad. Adhering to the concept of "Customer First, Quality Supreme", it continues to tackle technical problems and contribute to the development of China's industry.