I. What Is It and Where Is It Located?

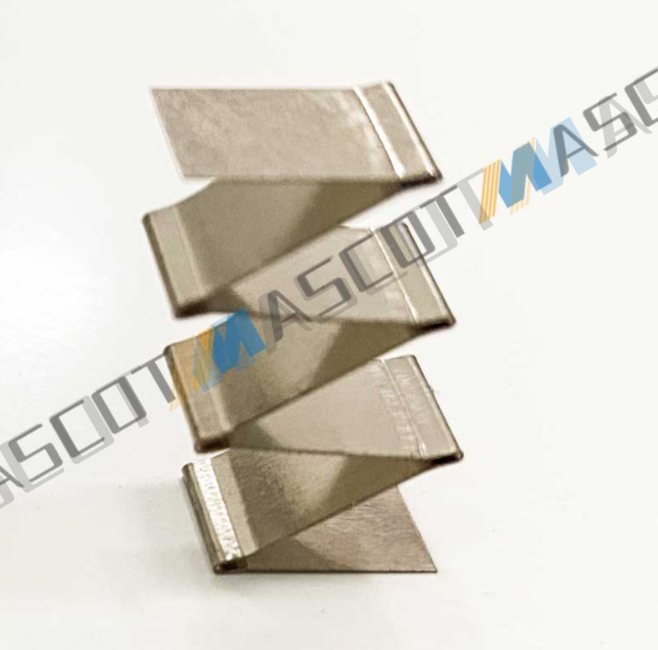

The folded spring is formed by continuously bending a spring strip. Its main "workspace" is attached to the clutch torsional vibration damper. You can think of it as a "buffer pad" or "shock absorber" in the clutch system, specifically responsible for absorbing and cushioning impacts and vibrations from the engine.

II. Core Mission: Why Is It So Important?

Its role can be summarized in three key points:

-

Cushioning Impact for Smoother Operation

Engine rotation is not perfectly uniform but involves periodic torsional vibrations. Especially during starting, gear shifting, and rapid acceleration, the transmission system is subjected to severe torque shocks. The folded spring absorbs this impact energy through its elastic deformation, converting it into gentle reciprocating motion. This results in smoother power engagement and significantly enhances driving comfort. -

Protecting the Transmission System and Extending Lifespan

Without this "buffer pad," massive impact forces would be directly transmitted to the gearbox, drive shaft, and even the wheels. Over time, this would accelerate wear and damage to critical components such as gears and bearings. The folded spring acts like a loyal guard, using its "flexible body" to protect the expensive transmission system behind it. -

Reducing Noise and Abnormal Sounds

Rigid impacts between metal components not only cause wear but also produce unpleasant noises and abnormal sounds. The effective buffering of the folded spring helps reduce such noise, creating a quieter driving environment for you.

III. Material Composition: Meeting Diverse Needs

The performance of the folded spring largely depends on its material. Mascot offers folded springs in various metal materials to meet the requirements of different application scenarios and performance needs:

-

Stainless Steel

Excellent corrosion resistance, suitable for vehicles with high anti-rust requirements or those exposed to corrosive media. Ensures stable performance and long service life even in harsh environments. -

Carbon Steel

High strength and excellent fatigue life, with high cost-effectiveness. A common and economical option, suitable for most ordinary household vehicle clutch systems, balancing performance and cost control. -

Alloy Steel

Extremely high strength, toughness, and fatigue resistance, designed for high-performance and high-load conditions. Commonly used in high-power cars, off-road vehicles, commercial trucks, or racing cars, capable of withstanding extreme working pressures and temperatures.

IV. Process and Advantages: Why "Folded"?

The unique "folding" manufacturing process brings three core advantages:

-

High Space Utilization

In the limited space of the clutch driven disc, the folded spring can provide the maximum elastic force with the smallest volume. -

Preloaded Stress

The pre-compression process creates beneficial pre-stress inside the spring, enabling it to withstand higher loads without permanent deformation. -

Long Fatigue Life

The folded spring, through precise design and treatment, far exceeds ordinary springs in fatigue resistance. It can endure millions or even tens of millions of reciprocating compressions, matching the lifespan of the vehicle.

For specific type wave spring selection guides or custom solutions, please contact the Mascot technical team immediately. We will provide you with tailored elastic solutions.

Call us at: 400-008-3858!