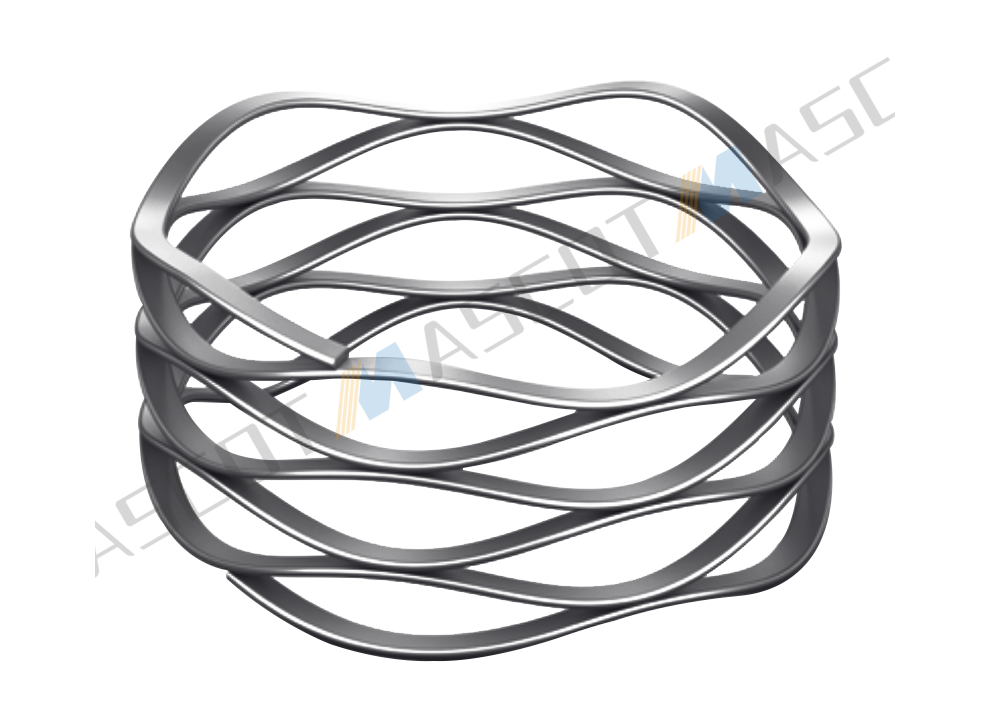

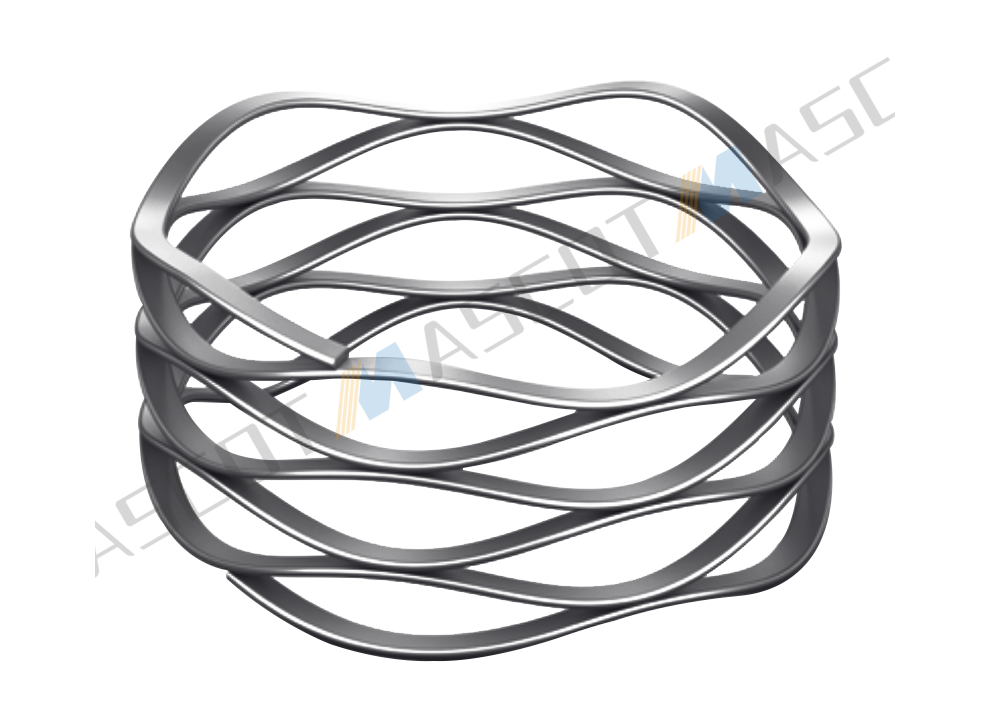

Wave springs, as compact and efficient elastic elements, play a crucial role in bearing systems, primarily used to provide axial preload, compensate for thermal expansion, and absorb vibration. Correct installation and selection are directly related to the bearing's service life and the overall machine's stability.

I. Core Installation Points

Installation Location Selection

Wave springs are typically installed between the bearing outer ring and the motor end cover (or bearing housing) to apply controllable axial pressure and eliminate bearing clearance. If multi-layer opposing wave springs are used, the "peak-to-valley" staggered arrangement of each layer must be maintained to ensure uniform load distribution and avoid eccentric loading.

Accurate Preload Control

The compression height of the spring must be strictly controlled during installation. The compression should be within its working stroke, and must never exceed the limiting compression height (generally not less than twice the wire thickness), otherwise, permanent deformation or early fracture may occur. Insufficient preload can lead to increased bearing clearance and unstable operation; excessive preload will accelerate fatigue failure of both the bearing and the spring.

Thermal Expansion Compensation Design

During motor operation, the shaft system experiences axial thermal expansion due to temperature rise. Wave springs can automatically compensate for such micro-displacements (material thermal expansion coefficient is approximately 11.5×10⁻⁶/°C), preventing the bearing from overheating and seizing due to being axially "locked," thereby enhancing system reliability.

Key Considerations

Before Installation: Always remove burrs and sharp edges inside the end cover mounting hole to prevent local sinking of the spring, which causes uneven stress.

During Installation: Ensure the flat end face of the spring is in complete contact with the end cover/shoulder. For flat-end opposing wave springs, which offer better support stability, they should be prioritized.

During Maintenance: Regularly inspect the spring condition, especially the interlayer contact of multi-layer wave springs for uniformity, to detect signs of fatigue promptly.

II. Failure Prevention Recommendations

The common failure mode of wave springs is fatigue fracture, mostly caused by axial overload, thermal stress concentration, or cyclic compression exceeding the material's fatigue limit. Mascot offers the following three recommendations:

1) Regarding Materials: It is recommended to use materials such as 17-7PH stainless steel, which is heat-resistant (up to 200°C), corrosion-resistant, and offers more stable performance.

2) In Design: Mechanical limiters can be incorporated into the system to strictly control the maximum compression stroke of the spring under dynamic conditions, avoiding accidental overload.

3) Spring Life Management: Fatigue life is strongly related to compression. Appropriately reducing the working compression (e.g., by 50%) can significantly extend service life.

Pursuing performance and long-term reliability for your bearing system? Mascot is your trustworthy partner.

We professionally provide a full range of high-performance wave spring solutions, with materials covering 17-7PH stainless steel, spring steel, carbon steel, etc., supporting custom specifications. Mascot products, with precise load control, excellent anti-fatigue characteristics, and strict process standards, ensure your bearing preload and compensation needs are perfectly met.

Contact Mascot now for professional selection support and solutions, making your design run more stably and last longer.