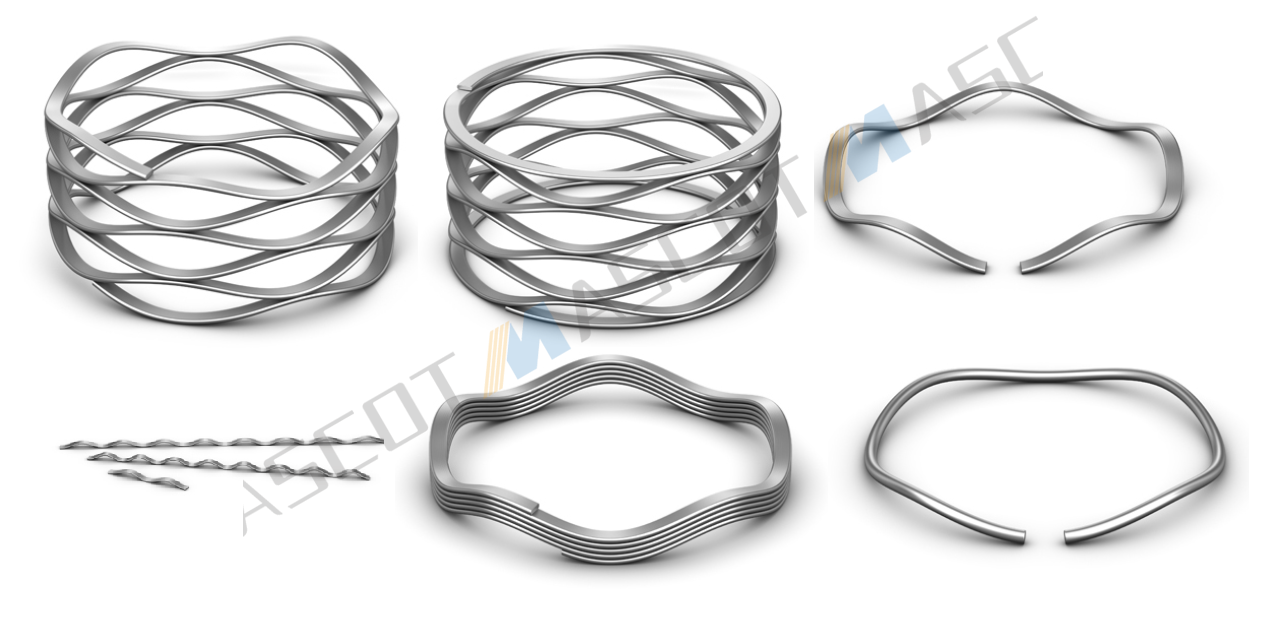

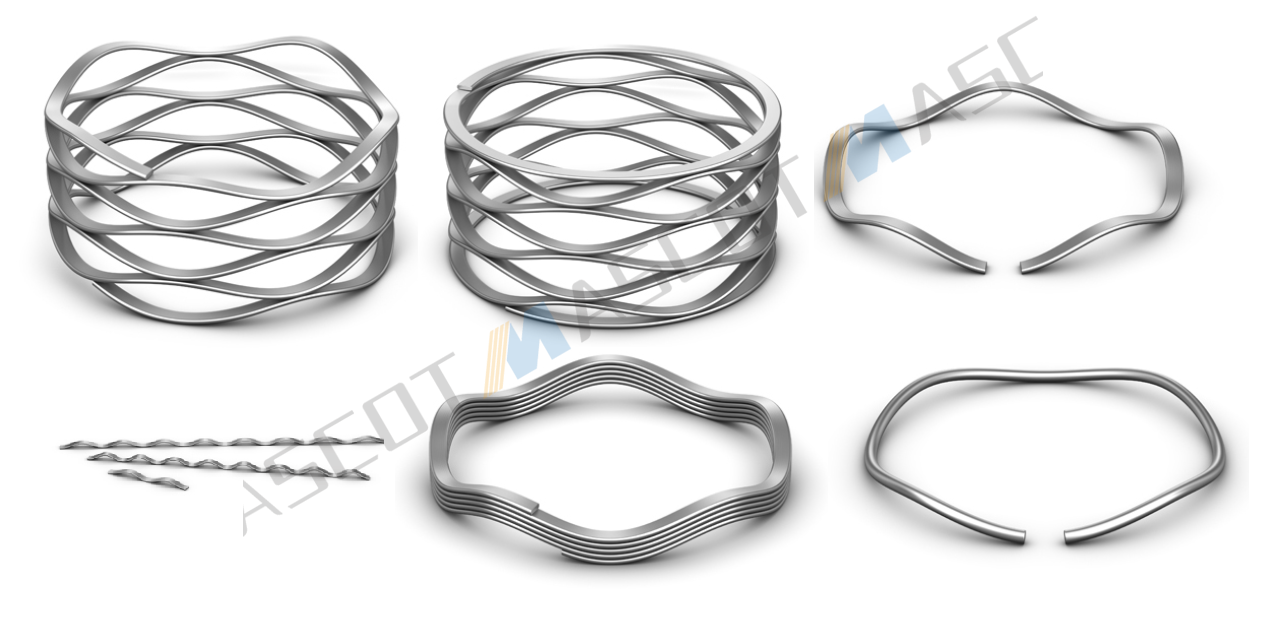

With their unique wave-shaped structure, wave springs can stably output elastic force and buffer in narrow spaces, and are widely used in precision machinery, electronic equipment, aerospace and other fields. When customizing, providing complete and accurate technical data to the manufacturer is the core prerequisite for the finished product to adapt to the working conditions. The following are the key technical information that need to be clarified.

I. Core Geometric Parameters: Laying the Foundation for Elastic Force and Assembly

Geometric dimensions determine the elasticity and adaptability of the spring and need to be accurately defined: Nominal diameter (inner diameter, outer diameter), indicating the shaft-mounted/hole-mounted scenario and reference tolerance; Wave parameters (wave crest and trough height, number of waves, wave shape), directly related to stiffness and stroke; Material cross-sectional dimensions (thickness, width), affecting bearing capacity and stability respectively; Free height and working height, used to calculate deformation and elastic force; Assembly space constraints (axial/radial), avoiding interference after compression.

II. Mechanical Performance Requirements: Ensuring Accurate Function Implementation

The core function of the wave spring is to provide specific elastic force, so its mechanical performance indicators must be clearly defined:

Stiffness requirement: The force required to compress the spring per unit length (N/mm or lb/in), and it is necessary to clarify whether it is linear stiffness or nonlinear characteristics.

Working load: The minimum and maximum loads that the spring needs to bear at the installation position or working state, as well as the corresponding deformation.

Preload requirement: If used for preloading or anti-loosening, the initial compression force after assembly shall be provided.

Fatigue life: Expected number of working cycles (e.g., >10⁶ cycles), which is particularly crucial for high-frequency or dynamic application scenarios.

III. Material and Process Selection: Adapting to Environmental and Service Life Requirements

Materials and surface treatments affect elasticity, corrosion resistance and service life, and need to be selected according to working conditions: In terms of materials, spring steel (such as 65Mn, etc.) is suitable for general industrial environments; Stainless steel (such as 302, etc.) is suitable for humid, corrosive or high and low temperature environments; Special alloys (such as Inconel, etc.) can withstand high temperatures/strong corrosion; Copper alloys and titanium alloys meet special needs such as electrical conductivity, magnetism resistance and light weight. Conventional processes such as galvanizing and passivation can be selected for surface treatment, and Teflon and epoxy coatings can be selected for special scenarios. At the same time, standards such as salt spray test and temperature resistance should be clarified. Of course, if you encounter difficulties in material selection, the technical team of Mascot will give relevant suggestions according to your working conditions.

IV. Tolerance and Precision: Ensuring Reliable and Consistent Assembly

Strict tolerance requirements are required for precision scenarios: Dimensional tolerance (key dimensions such as inner diameter and outer diameter, e.g., ±0.1mm); Geometric tolerance (flatness, parallelism, etc., ensuring uniform force bearing); Load tolerance (stiffness or load error range, e.g., ±10%).

V. Service Environment and Working Conditions: Core Basis for Customization Optimization

Working conditions are the key premise for determining the custom wave spring scheme, directly affecting material selection, structural design and performance optimization direction. It is necessary to specify in detail the ambient temperature range during equipment operation (e.g., -50℃ to 180℃), which directly determines the temperature resistance requirements of the material; Medium type (such as lubricating oil, water, corrosive gas or specific chemicals), used to evaluate the corrosion resistance of the material; Vibration and impact conditions (such as amplitude, frequency, impact load magnitude), to design the buffer and anti-fatigue characteristics of the spring; As well as equipment operating speed, load cycle characteristics (such as static preload or dynamic alternating load), etc., to ensure that the wave spring can not only meet the functional requirements but also maintain long-term stable service life under actual working conditions.

Therefore, customizing wave springs requires collaboration between supply and demand. The more detailed and accurate the information, the more reliable the finished product. It is recommended to attach drawings, working condition descriptions or samples during communication to ensure consistent understanding and efficiently promote the process.