In the operation of pump and valve equipment, although seals are small components, they directly determine equipment efficiency and safety. According to industry data, more than 30% of pump and valve failures stem from seal failure. Minor failures may lead to shutdowns for maintenance, while severe ones can cause medium leakage, production line paralysis, and million-level losses. Based on years of production and supporting experience, we analyze selection techniques from core dimensions to help industry peers avoid pitfalls and improve efficiency.

I. Precisely Match Working Conditions: The Core Premise of Selection

Working condition parameters are the fundamental basis for selection, requiring focus on four key dimensions. In terms of pressure, spiral wound gaskets are suitable for low-pressure conditions (<10MPa); hollow inert gas-filled metal O-rings are compatible with 10-70MPa; and Inconel C-rings are preferred for pressures exceeding 70MPa, as their blade-like structure enables stress concentration sealing. For temperature, 304 stainless steel can be used for -200~300℃, 316Ti stainless steel is upgraded for 300~550℃, and molybdenum alloy gold-plated materials are required for temperatures above 750℃.

Medium characteristics directly determine material compatibility: PTFE materials are selected for strong acid environments, 304 stainless steel is prohibited for chlorine-containing media, and nitrile rubber (NBR) is sufficient for neutral oil. For dynamic sealing, additional attention should be paid to rotational speed; mechanical seals are recommended for speeds exceeding 1000rpm, as they have stable friction coefficients and adapt to the impact of high-speed centrifugal force.

II. Scientific Material Selection: Balancing Performance and Cost

Material selection must balance working condition adaptability and cost-effectiveness. Among elastomer materials, fluoroelastomer (FKM) has excellent high-temperature and corrosion resistance, suitable for harsh conditions but with higher cost; ethylene propylene diene monomer (EPDM) is resistant to ozone aging and compatible with acid and alkali media; nitrile rubber offers outstanding cost-effectiveness and is applicable to general oil scenarios. Polyurethane (PU) seals have extremely strong wear resistance and high tensile strength, suitable for hydraulic systems and reciprocating motion sealing scenarios, with better tear resistance than most elastomers; polytetrafluoroethylene (PTFE) seals have almost universal corrosion resistance, a wide temperature range (-200~260℃), and extremely low friction coefficients, making them suitable for strong corrosion, high cleanliness, and low-temperature conditions. It should be noted that PTFE has poor elasticity and often needs to be used with elastic substrates.

III. Adapting Structure and Avoiding Pitfalls: Manufacturer's Practical Reminders

Seal structures must match installation methods: O-rings and rectangular rings are optional for static sealing (flanges, valves), while dynamic sealing (pump shafts) requires spring-energized structures. Dimensional accuracy is crucial, and the compression ratio must be reasonable—excessively high compression can cause deformation and damage, while excessively low compression leads to seal failure.

Avoiding common misunderstandings is key to extending service life: Do not use solid metal O-rings for rotating shaft seals, as they are prone to wear and seizing within 3 hours; reserve temperature margins for high-temperature conditions to prevent sudden service life reduction due to actual temperatures exceeding material limits; never over-rely on supplier recommendations—proactively provide complete working condition parameters.

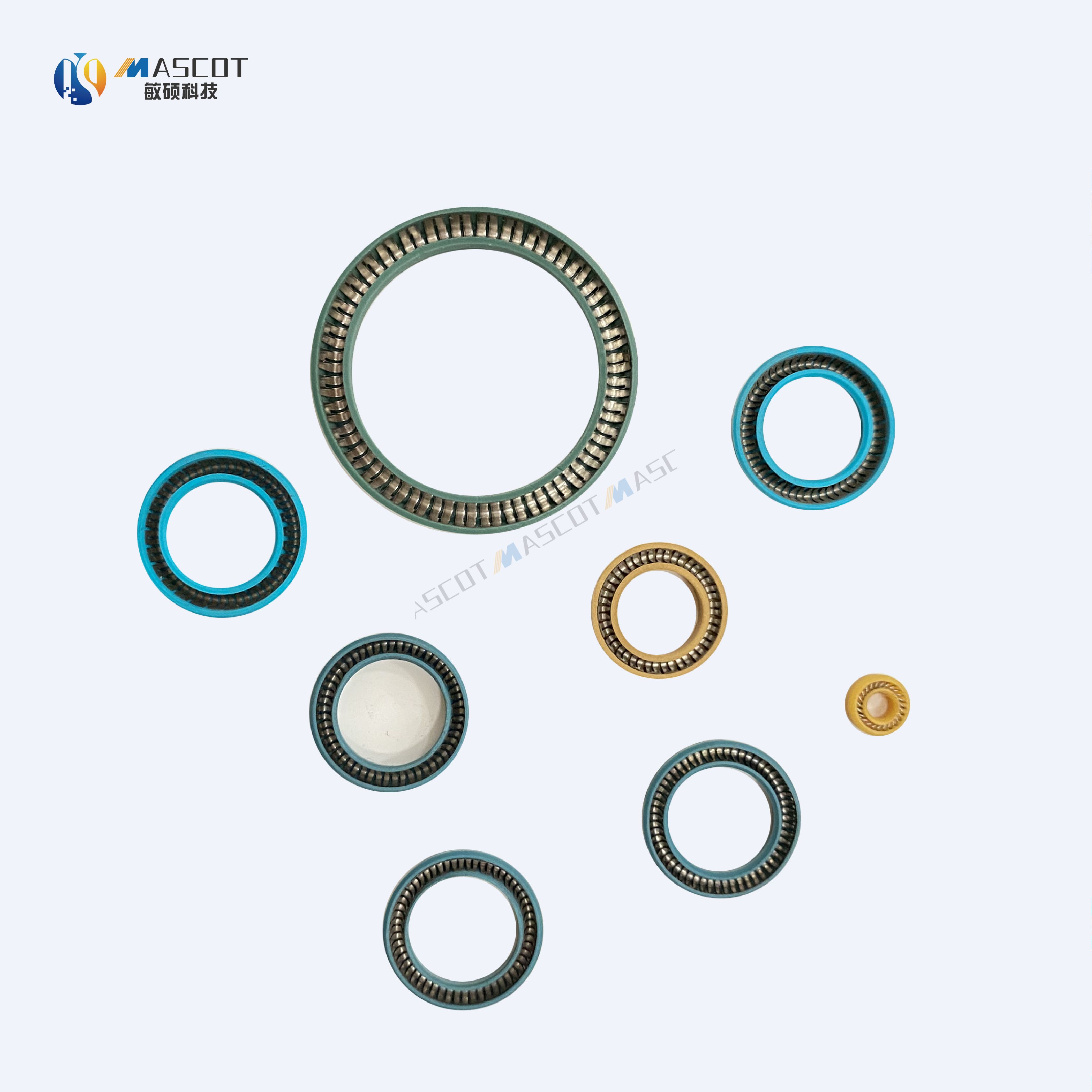

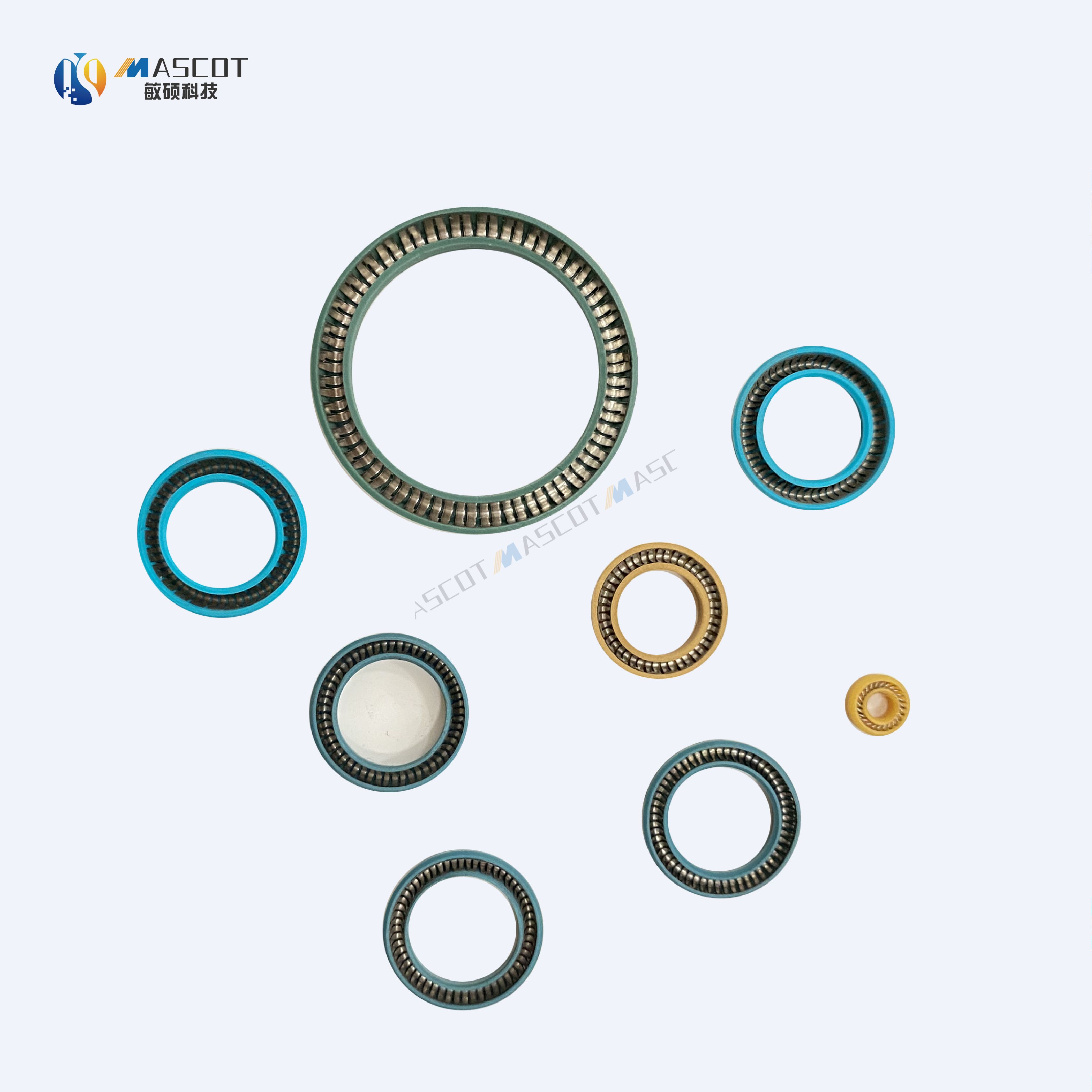

In summary, seal selection must follow the principle of "taking working conditions as the benchmark, adapting materials, and supplementing structural details." For complex working conditions, it is recommended to conduct sample bench tests first to verify compatibility and durability. Choosing qualified suppliers can provide customized solutions and ensure long-term stable operation of pump and valve equipment from the source. As a source manufacturer with 20 years of experience in the sealing field, Mascot has built a full-chain service system relying on multiple international quality certifications and exclusive material formulas. Catering to the needs of the pump and valve industry, Mascot provides customized solution services, accompanied by working condition analysis and technical support. It has supplied high-reliability sealing solutions for new energy, aerospace, petroleum, and other fields, making it a preferred partner for pump and valve enterprises in selection and cooperation.