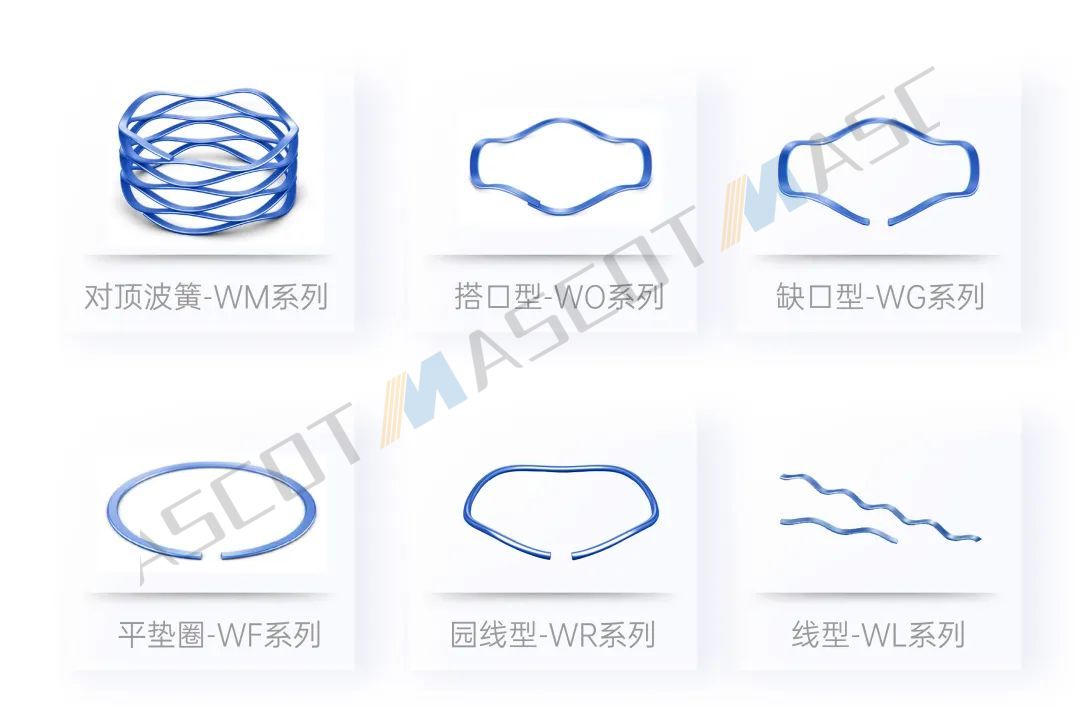

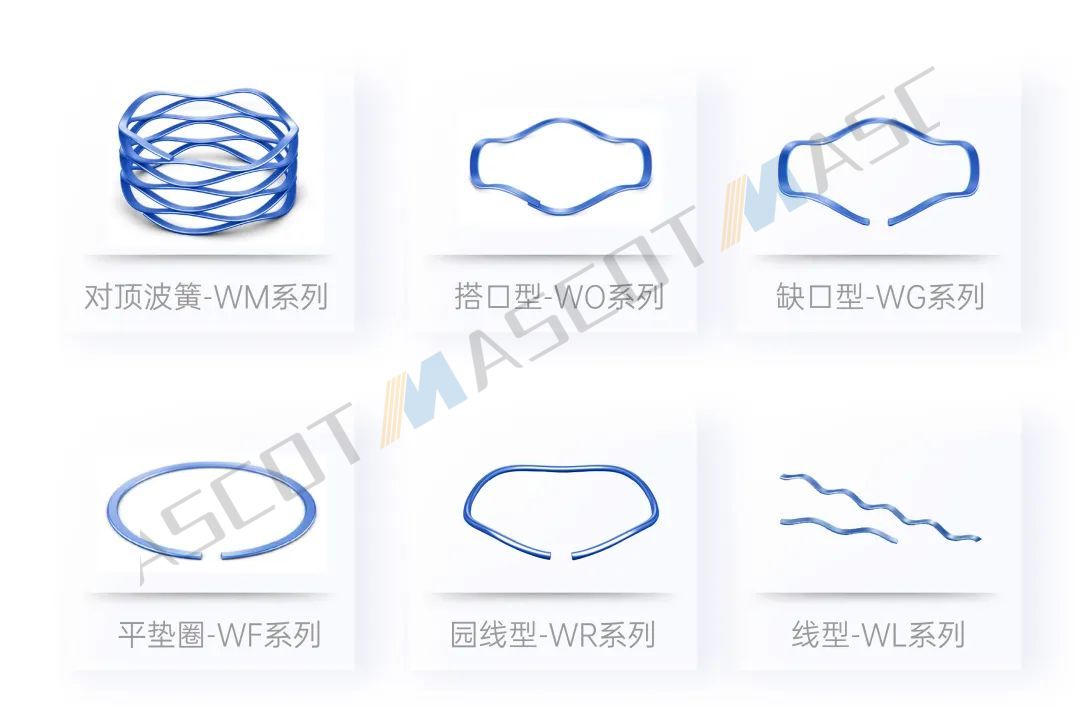

With the continuous advancement of industrialization, China's industrial upgrading has accelerated. The wave springs of the Mascot brand have been widely applied in numerous fields, especially in the product design of aerospace, precision machinery, hydraulic sealing, and high-end motors, providing numerous compact and lightweight solutions. All of this is attributed to its three prominent features: space-saving, high precision, and high quality.

Space-saving: The wave springs of Mascot have a unique advantage of space-saving, capable of saving up to 50% of space and can be used to replace coil springs. By reducing the working height of the spring, the wave spring also decreases the volume of the spring cavity. It achieves cost savings through smaller component sizes and less manufacturing materials.

High precision: Wave springs are load-bearing devices. They occupy gaps and compensate for dimensional changes in the device. By gradually accumulating or suddenly changing the load to reach the predetermined working strength, wave springs can generate almost any range of force. Thus, an accurate elastic ratio proportional to the load and deformation can be established.

High quality: No matter from which angle or standard to evaluate, the reliability and performance of wave springs are significantly beyond the general level. The reason why these springs can reach such high performance standards is that they are made of fully hardened materials that have been carefully tempered. This material treatment method ensures that the springs will not deform due to improper hardening during use, thereby greatly improving their stability and durability.