In numerous systems such as industrial equipment, automotive components, and medical devices, there is a seemingly unremarkable yet vital part - the sealing ring. This small annular component, with its unique structure and performance, has become an important component ensuring the stable operation of systems. Today, we will delve into the core roles of sealing rings and why they have become indispensable components in various industries.

I. Sealing: An Important Line of Defense Against Leakage

The core mission of a sealing ring is to achieve effective sealing. Whether it is high-pressure oil flowing in hydraulic systems, compressed air in pneumatic equipment, or water flow in water pipes, once leakage occurs at interfaces or connections, it will not only cause medium waste but also may lead to equipment failures, reduced efficiency, and even safety hazards.

Sealing rings form a physical barrier by closely fitting the surface of the parts that need to be sealed through their own elastic deformation. For example, in the battery compartment of new energy vehicles, the sealing ring needs to withstand temperature fluctuations from -40℃ to 85℃ and resist corrosion from battery electrolytes to ensure the interior of the compartment is dry and free of dust. In industrial hydraulic presses, it must maintain sealing under certain pressure to prevent power loss caused by hydraulic oil leakage.

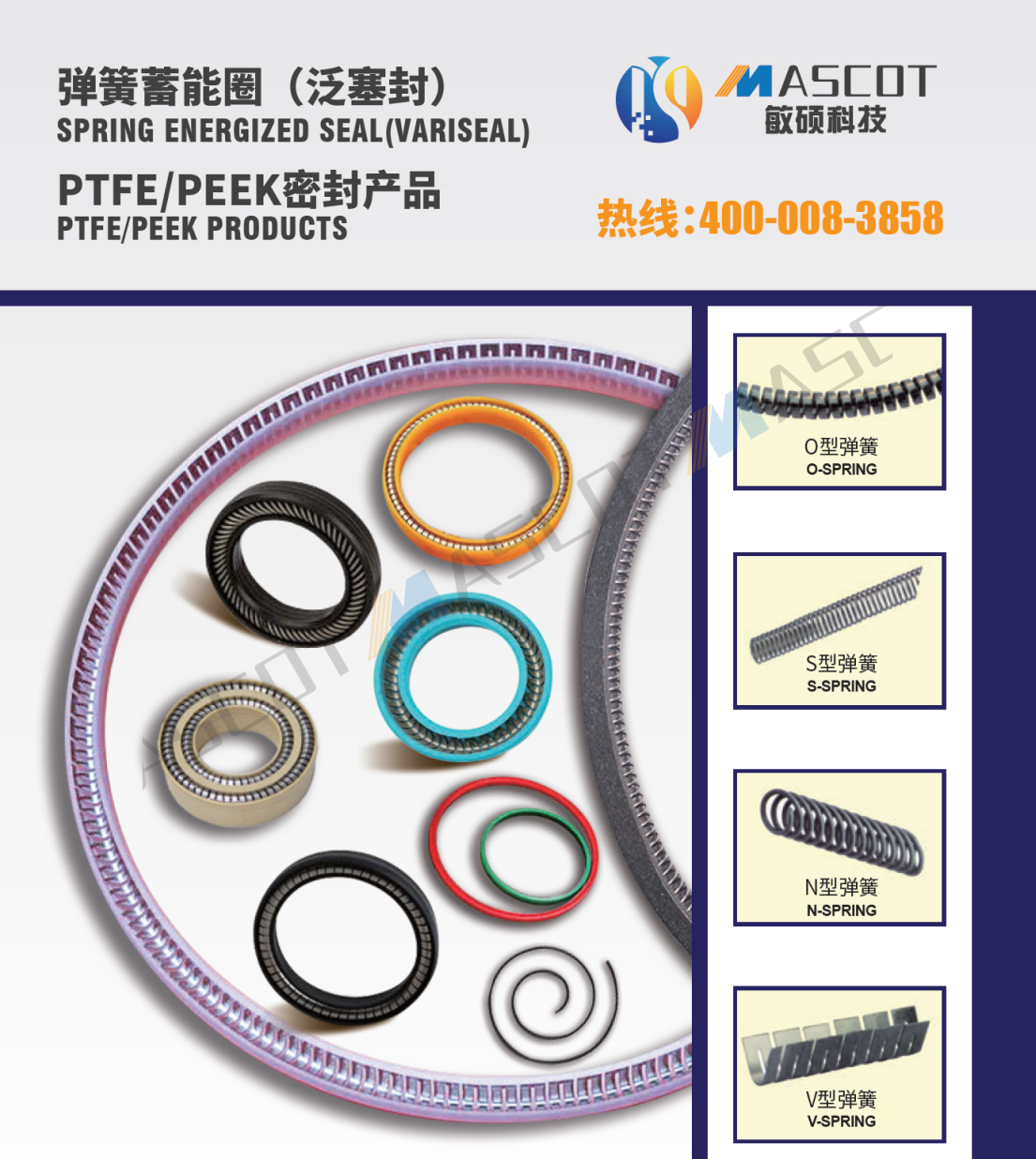

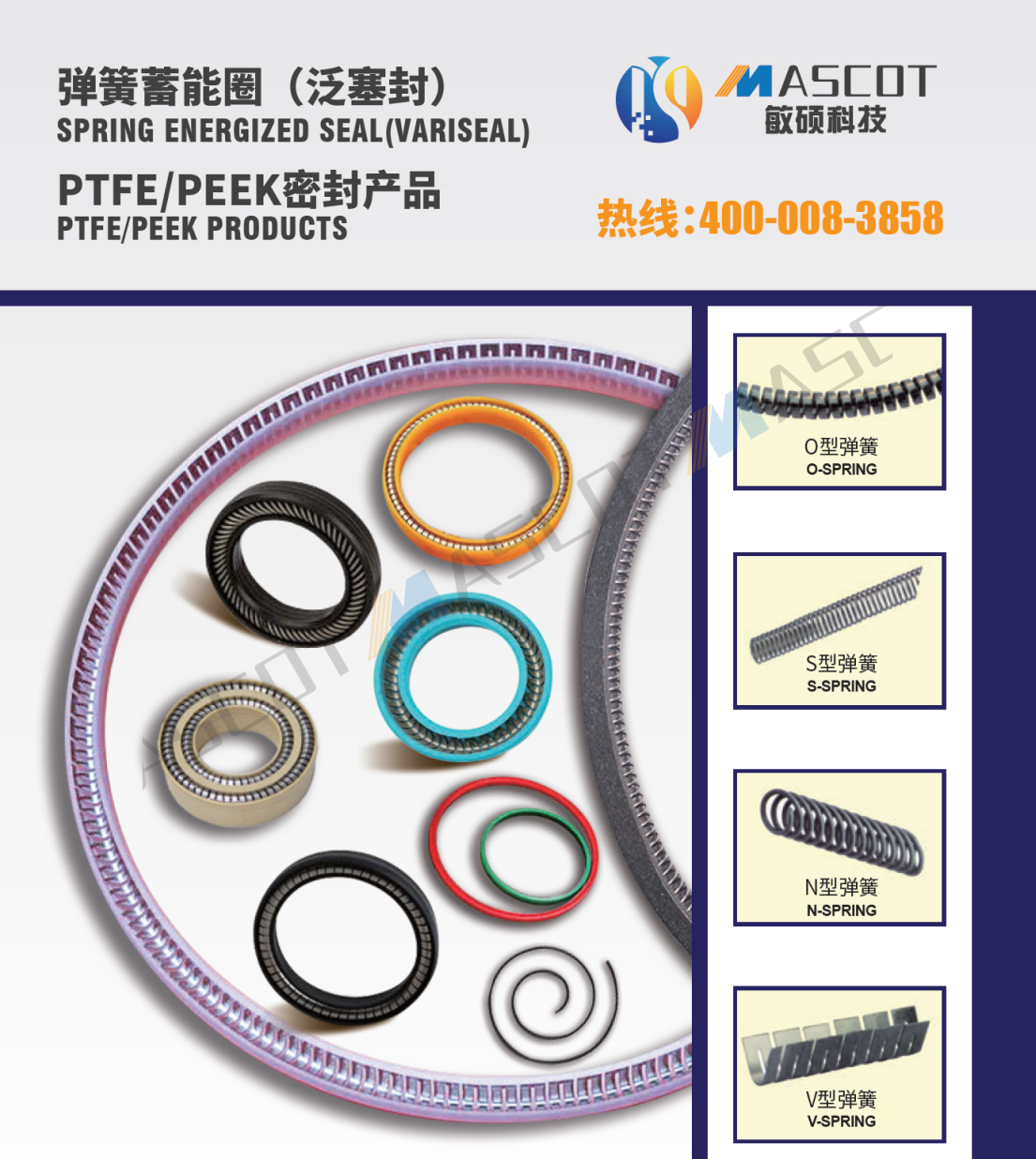

Mascot Technology's sealing rings, with precise size control (tolerance can be controlled within ±0.02mm) and materials with good weather resistance (such as fluororubber, silicone rubber, etc.), can adapt to different media, pressure, and temperature scenarios, building a reliable "leakage prevention line" for various systems.

II. Buffering and Shock Absorption: A "Flexible Cushion" to Reduce Wear

In addition to sealing, sealing rings also act as "buffers" between relatively moving parts. In the precision pump bodies of medical devices, if the reciprocating movement of the piston and cylinder comes into direct contact, it is prone to wear and noise due to friction. In the vibrating environment of automobile engines, rigid collisions of metal parts may lead to loose connections.

At this time, the elastic characteristics of the sealing ring can come into play: it can absorb the impact force generated by movement, reduce direct friction between parts, thereby reducing the wear rate and extending the service life of the equipment. For example, in infusion pumps, the custom-made medical-grade sealing rings by Mascot can reduce the vibration amplitude of components by more than 40% and control the operating noise below 30 decibels, which not only ensures the precision of the equipment but also improves the user experience.

III. Enhancing System Reliability: A "Stabilizer" to Cope with Complex Environments

Industrial environments are often full of challenges - high temperature, low temperature, humidity, chemical corrosion, high pressure, etc. These factors may affect the stability of the system. However, high-quality sealing rings can maintain stable performance in changing environments, helping to improve the reliability of the system.

For example, in nuclear power equipment, sealing rings need to withstand radiation and high temperatures for a long time, and the anti-aging property of their materials is directly related to the safe operation of the equipment. In food processing machinery, sealing rings must comply with food-grade certifications (such as FDA standards) to ensure that no harmful substances are released when in contact with food ingredients. Through customized material formulas and process optimization, Mascot Technology enables sealing rings to resist high pressure in deep-sea detection equipment and adapt to vacuum environments in aerospace components, providing multi-scenario guarantees for systems in different industries.

Conclusion: Choose the Right Sealing Ring to Make the System More "Worry-Free"

A seemingly simple sealing ring is actually a precise combination of technology and scenario requirements. From preventing leakage to buffering and shock absorption, and then to resisting complex environments, each of its roles directly affects the efficiency, service life, and safety of the equipment.

As a provider of sealing solutions, Mascot Technology focuses on "detail control". Whether it is material selection, structural design, or production processes, it aims to "adapt to scenarios and meet needs", providing customers with a full range of sealing products from conventional models to customized solutions. Choosing the right sealing ring can reduce leakage problems in your system, making it run more stably and durably.