In the modern industrial system, sealing technology is crucial for ensuring the stable operation of equipment. PTFE spring energized seals, with their excellent performance, have become important components in many industries.

I. Basic Characteristics

(I) Advantages of Material Performance

Chemical inertness and corrosion resistance: The main body is made of polytetrafluoroethylene (PTFE), which can resist the erosion of most chemical substances such as strong acids and alkalis, and is an important choice for sealing in chemical, pharmaceutical and other industries. For example, in chemical reaction kettles, it can withstand corrosive media for a long time, helping to ensure production safety.

Wide temperature adaptation range: The working temperature ranges from -200°C to 260°C, and it can maintain stable sealing in low-temperature environments such as liquefied natural gas equipment and high-temperature scenarios such as high-temperature industrial furnaces.

Low friction coefficient and self-lubrication: The low friction characteristic of PTFE reduces the wear of moving parts of equipment. For example, in hydraulic cylinders, it can improve the smoothness of operation and extend the service life.

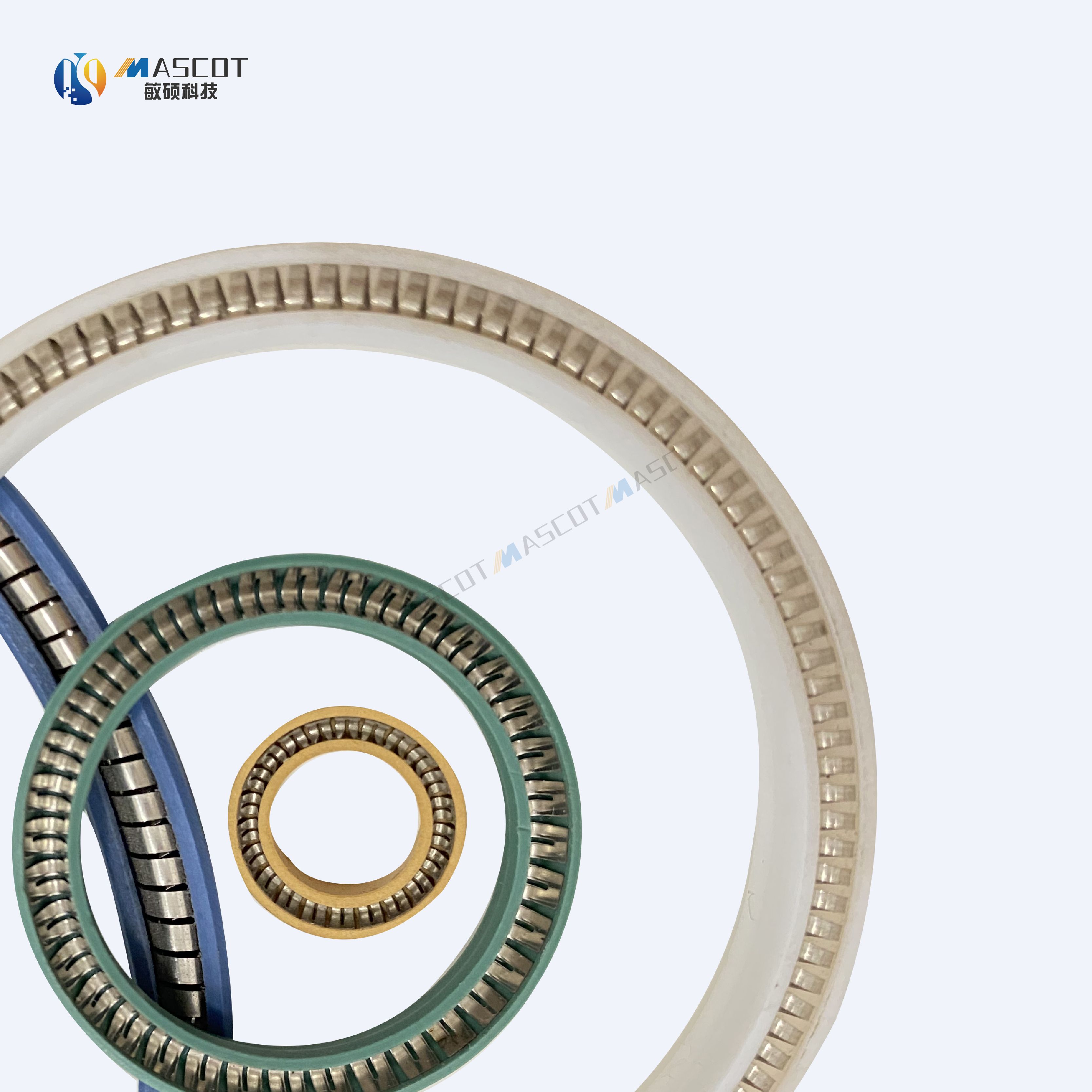

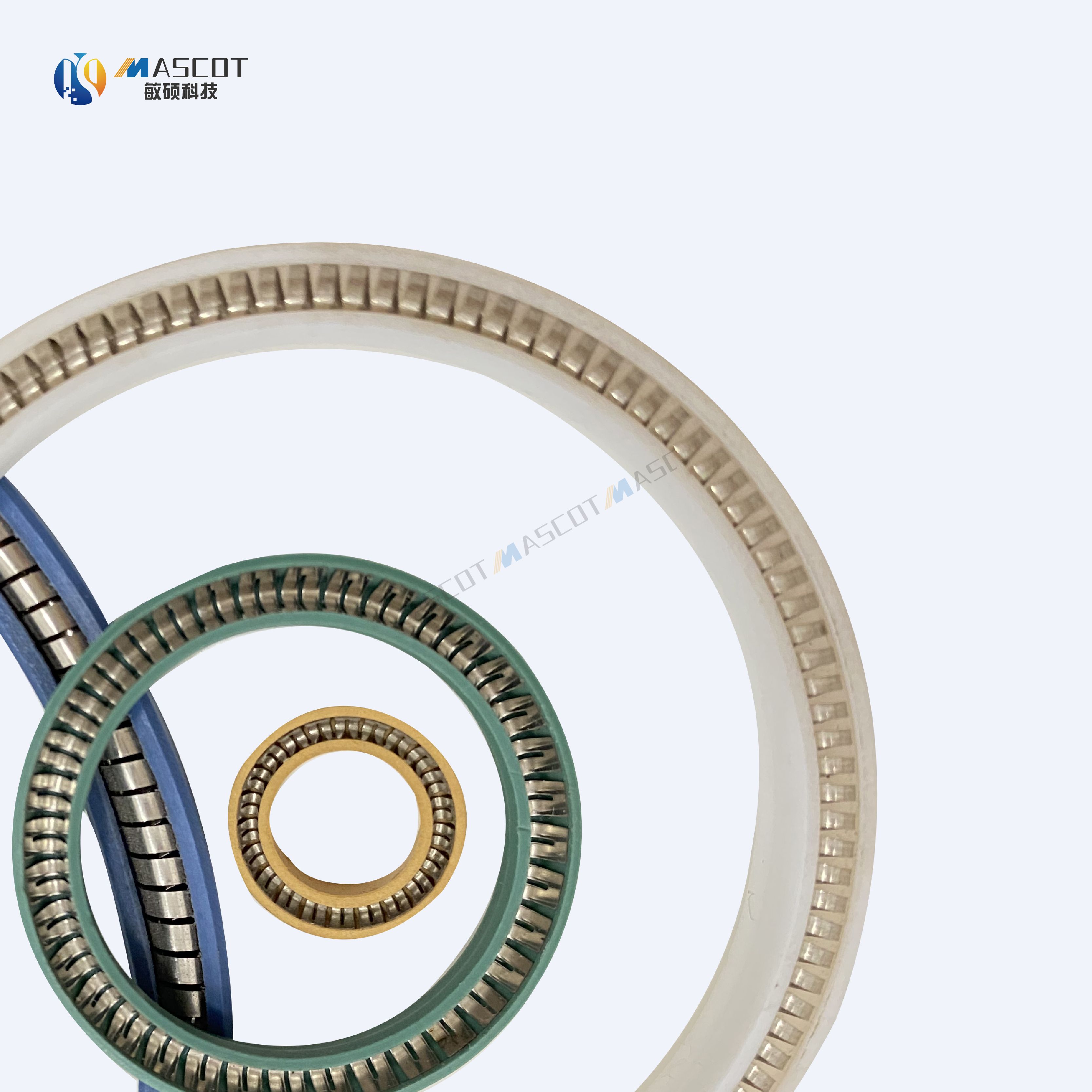

(II) Advantages of Unique Structural Design

Spring energy storage mechanism: The internal spring cooperates with the system pressure to make the sealing lip closely fit the metal surface, which can adapt to slight eccentricity of the metal surface and wear of the sealing lip, ensuring the sealing effect in scenarios such as rotating equipment.

Flexible cross-section and sealing lip design: The cross-section can be designed into V-shape, X-shape, etc. The V-shape is conducive to dispersing high pressure, and the X-shape is suitable for two-way sealing; the multi-layer sealing lip enhances the sealing, which is applicable to scenarios with high sealing requirements such as vacuum equipment.

II. Application Fields

(I) Industrial Manufacturing Field

In the chemical industry, it is used in key parts such as reaction kettles and pumps to cope with high temperature, high pressure and corrosive media; in the oil and gas industry, it is suitable for downhole tools, oil pipeline valves, etc., ensuring sealing in complex environments such as deep-sea mining; in the food and pharmaceutical industries, the materials meet hygiene standards, helping to ensure a clean production environment.

(II) Mechanical Engineering Field

In hydraulic and pneumatic systems, it improves system response and efficiency, ensuring the normal operation of large construction machinery; provides solutions for the shaft seals of rotating equipment such as motors and pumps, extending the service life of equipment.

(III) Other Fields

In the aerospace field, it meets the sealing requirements of aero-engines, spacecraft propulsion systems, etc. in extreme environments; in the automotive industry, it is applied to engines, air conditioning systems, etc., helping to improve vehicle performance and reliability; in the robot field, it plays an important role in parts such as joints and hydraulic drive components of industrial robots. Industrial robots often need to move at high frequencies in dusty, humid environments or even with a small amount of corrosive substances. The low friction characteristic of PTFE spring energized seals can ensure flexible joint movement, and their wear resistance and corrosion resistance can extend the maintenance cycle of robots, helping to ensure their long-term stable work.

III. Important Role in Industrial Sealing

It can prevent the leakage of dangerous media, reduce equipment failures and maintenance costs, and help ensure production safety; ensure the continuity of the production process, which is conducive to ensuring stable product quality, such as maintaining a sterile environment in pharmaceutical workshops; can cope with extreme working conditions such as high temperature and high pressure, and its research, development and application have a positive promoting effect on the innovation and upgrading of industrial sealing technology.