1. Define the Application Scenario to Match Material Properties

Different working conditions demand different sealing solutions:

-

High-temperature environments (e.g., engines, chemical equipment): PTFE (Polytetrafluoroethylene) sealing rings are recommended for their heat resistance, low friction, and self-lubricating properties, which reduce wear and extend service life.

-

Food/pharmaceutical industries: Must use FDA-certified non-toxic, odorless, and corrosion-resistant materials, such as silicone or specialty rubber.

-

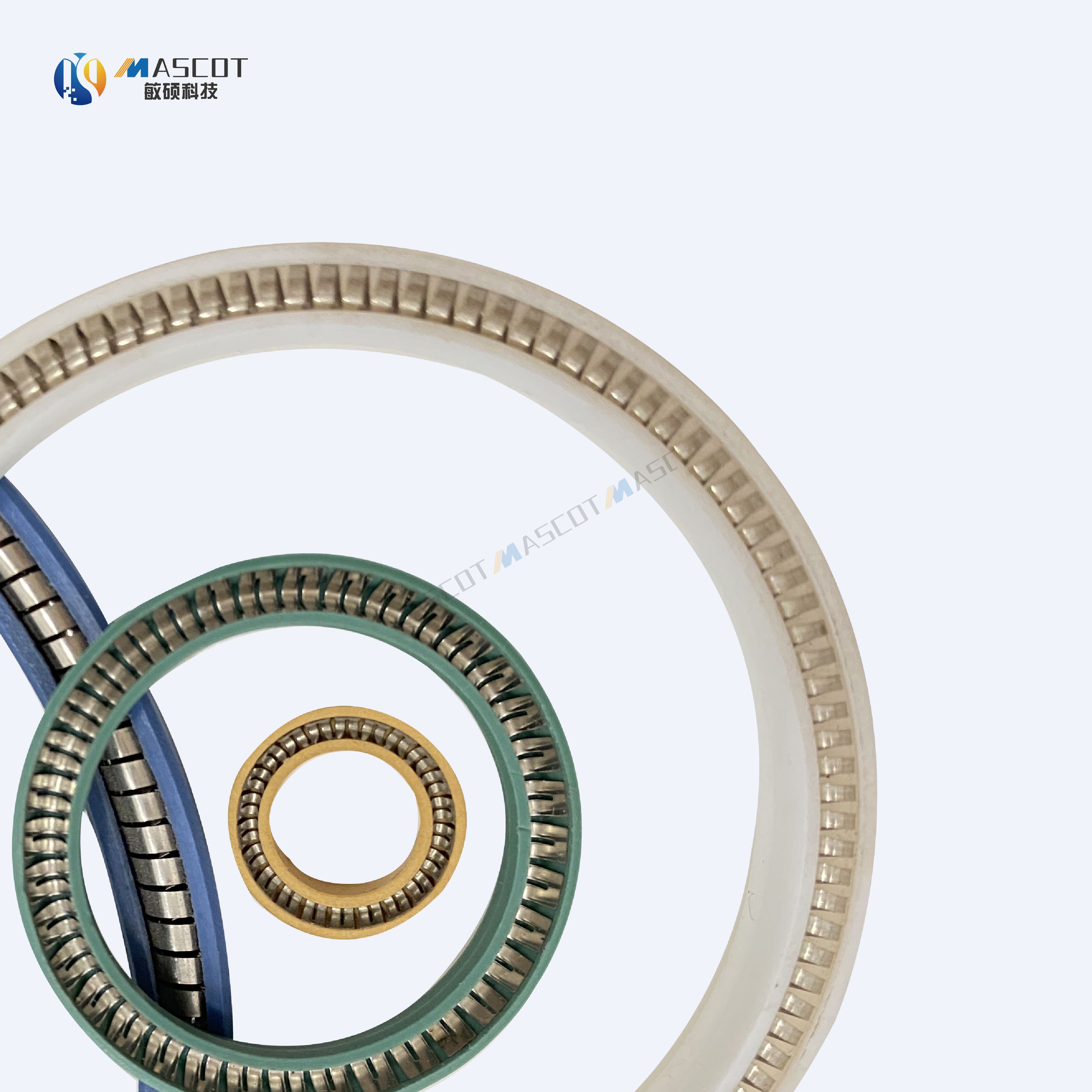

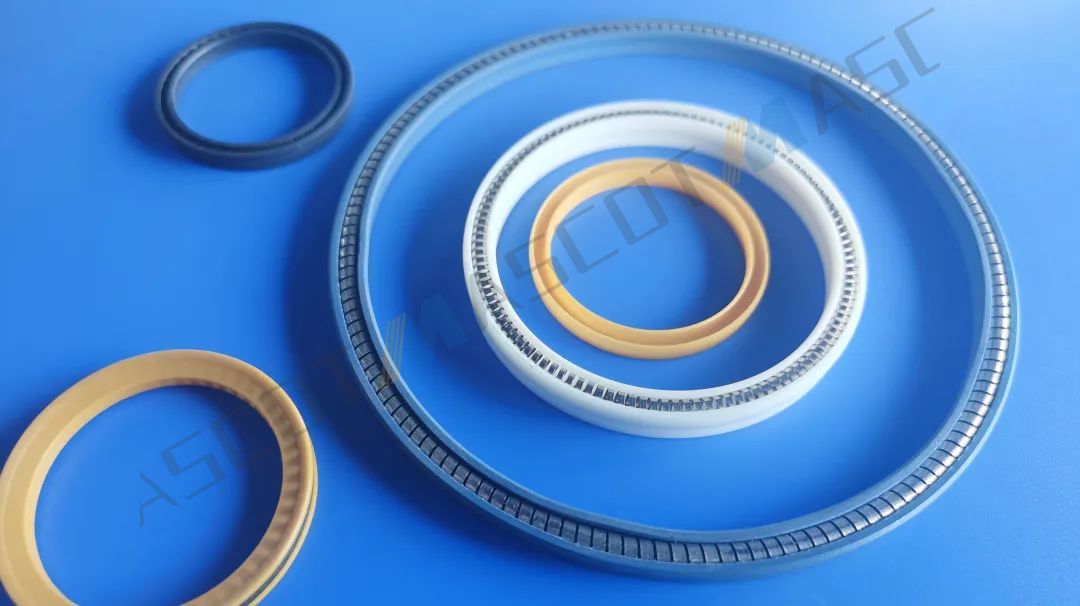

High-pressure/dynamic sealing: Consider spring-energized seals (e.g., Mascot’s metal spring-enhanced sealing rings), whose unique elastic structure adapts to pressure fluctuations, ensuring long-term sealing reliability.

2. Match Working Pressure and Temperature Ranges Accurately

The pressure and temperature resistance of sealing rings directly impact their lifespan and performance:

-

Standard rubber seals are typically suitable for low-pressure, moderate-temperature (-30°C to 120°C) applications.

-

For high-pressure (>10MPa) or ultra-high-temperature (>200°C) environments, opt for PTFE or composite material seals, such as Mascot’s innovative PEEK sealing rings. Made from high-performance engineering polymers, they offer superior heat resistance compared to PTFE, providing reliable sealing solutions for extreme conditions.

3. Prioritize Wear and Aging Resistance to Reduce Maintenance Costs

Wear and aging resistance are critical indicators of sealing ring quality. Frequent replacements not only increase costs but also disrupt equipment operation. Spring-energized seals are an excellent choice—their metal spring design ensures low friction while resisting material aging, delivering extended service life.

4. Choose Reliable Brands for Long-Term Stability

Reputable brands typically offer mature manufacturing processes and strict quality control. When selecting, prioritize well-reviewed brands and consider real user feedback. For example, Mascot Seals are widely used in aerospace, petrochemical, and semiconductor equipment, undergoing precision machining and rigorous testing to ensure stable performance even in extreme conditions.

Conclusion: 4 Steps to the Perfect Seal

-

Assess the application—high temperature, food-grade, or dynamic sealing?

-

Check specifications—does it match pressure and temperature requirements?

-

Evaluate durability—is it wear-resistant and aging-proof?

-

Verify brand reputation—is it proven in the market?

By following this approach and leveraging Mascot’s expertise, you can find high-performance, long-lasting sealing solutions to ensure smooth equipment operation with minimal maintenance.

For sealing ring inquiries, visit our official website or contact us at 400-008-3858!