In complex industrial equipment, gaskets, though seemingly small, undertake a crucial mission. They silently fill the gaps between metal flanges, effectively preventing the leakage of harmful media and safeguarding the integrity and safety of the entire system. Among them, polytetrafluoroethylene (PTFE) gaskets, with their excellent comprehensive performance, have become the preferred sealing solution for numerous harsh working conditions.

I. User Pain Points

Although PTFE materials offer many advantages, they also have obvious limitations, the most prominent of which is their "cold flow" property (i.e., creep phenomenon). Under the action of continuous load, gaskets will gradually undergo plastic deformation and thickness reduction, leading to a decrease in flange fastening force and eventually triggering leakage risks.

To alleviate the creep problem of pure PTFE, the early practice of using PTFE-coated rubber gaskets was adopted. However, this method still has certain drawbacks: the rubber matrix has poor chemical resistance and is prone to swelling when exposed to organic solvents; its mechanical strength is limited; and the outer PTFE film is easily damaged, resulting in medium erosion and seal failure.

In addition, PTFE gaskets have a large coefficient of linear expansion (about 10-20 times that of steel), showing instability with temperature changes, poor thermal conductivity, and decomposing to release toxic gases in high-temperature environments above 400°C. These factors all bring additional challenges to users in practical engineering applications.

II. Solutions and Technical Innovations

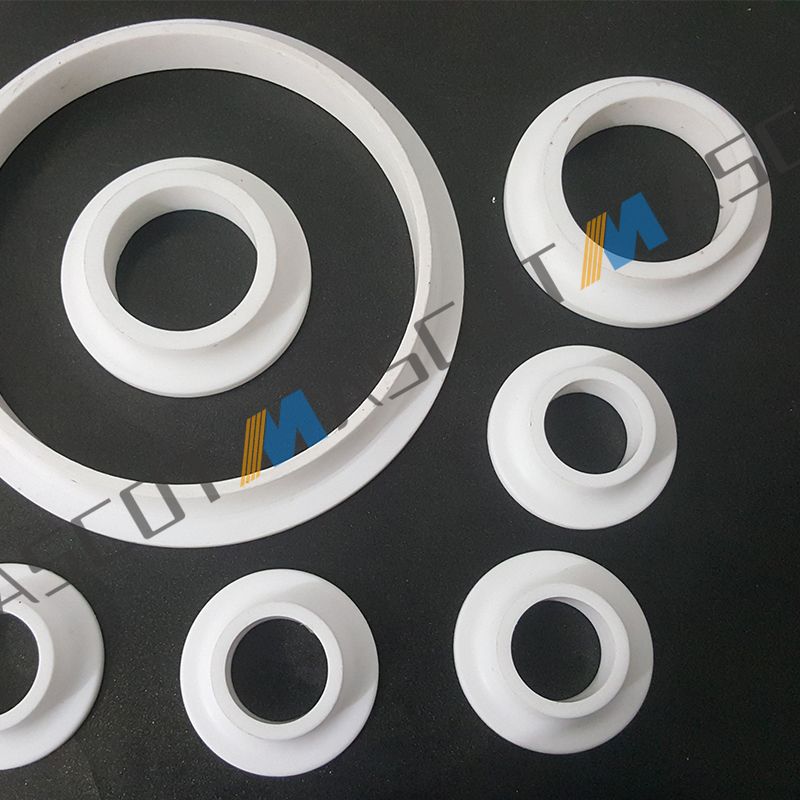

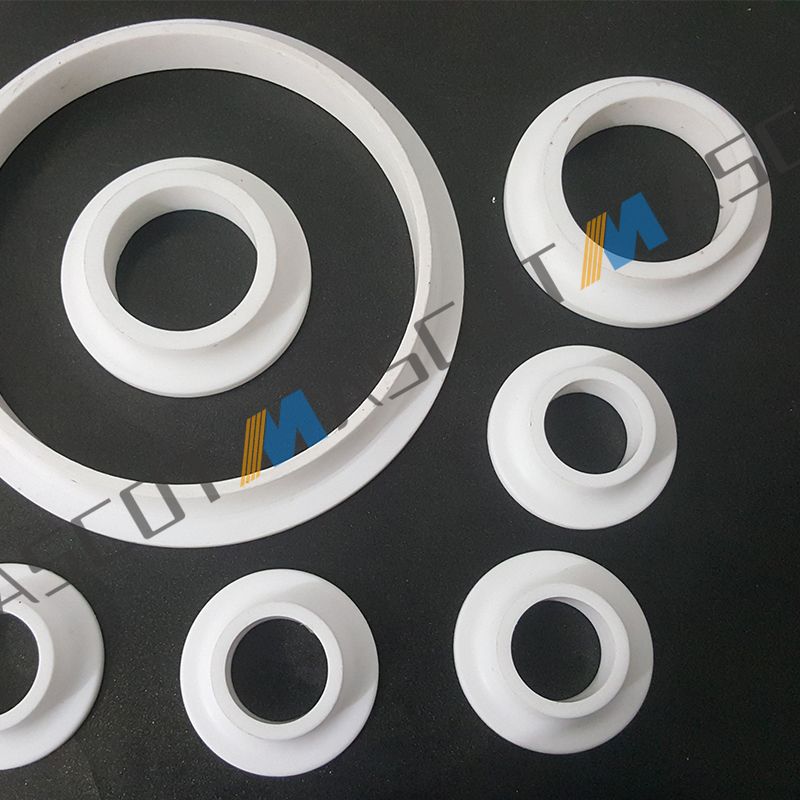

To solve the creep problem of PTFE, filler modification has become an effective means to improve its sealing performance. For example, the multi-layer composite filled PTFE gaskets developed by Mascot Technology introduce specific fillers into the material, significantly enhancing anti-compression and rebound performance. Such products have an extremely low friction coefficient, no crawling phenomenon, and excellent self-lubricating performance, enabling stable operation even in the absence of sufficient lubrication.

Another innovative approach is the adoption of a composite structure design, such as PTFE/EPDM composite gaskets. This product uses high-quality ethylene propylene diene monomer (EPDM) as the main body and composites a specially activated pure PTFE outer layer at key sealing positions. This structure effectively inhibits the cold flow tendency of the gasket, enhances anti-blowout capability, and overall exhibits good rigidity, compression rebound performance, and compensability. Its raised sealing ring design reduces the contact area with the flange, helping to maintain high sealing specific pressure, thereby lowering bolt torque requirements and improving sealing efficiency.

Through continuous optimization of material formulas, structural innovation, and precision manufacturing processes, Mascot continuously strengthens the anti-creep performance and sealing reliability of PTFE gaskets, providing safer and more stable sealing solutions for users in various industries.