A Complete Analysis of O-Ring Standard Size Specifications

As a fundamental and critical sealing component, the performance of an O-Ring directly impacts the reliability of the entire sealing system. To ensure O-Rings function as intended, an in-depth understanding of their standard size specification system is the primary prerequisite. This article will start with the core parameters of O-Rings, systematically outline the differences between major standards, detail the matching principles with groove design, and provide a clear application selection guide, offering a solid technical basis for your sealing solutions.

I. Basic Standards & Core Parameters

The standard size specifications for O-Rings are based on cross-section diameter and inner diameter as core parameters. The cross-section diameter range is 0.1~15 mm, and the inner diameter can reach 1~2000 mm. The Chinese National Standard GB/T 3452.1-2005 specifies mainstream specifications, such as series with cross-section diameters of 1.8 mm, 2.65 mm, and 3.55 mm, along with inner diameter combinations like 4×1.8 (4 mm inner diameter, 1.8 mm cross-section) and 71×2.65 (71 mm inner diameter, 2.65 mm cross-section).

Tolerance control is a key factor in O-Ring standard size specifications. For example, when the cross-section is 1.8 mm, the tolerance is ±0.08 mm; when the inner diameter is 19 mm, the tolerance is ±0.22 mm.

The International Standard ISO 3601 is divided into Class A (compatible with the American standard AS568B) and Class B (metric alternative). The inner diameter unit uniformly adopts 0.1 mm level precision to ensure global compatibility.

II. International & National Standard Systems

Global O-Ring standard size specifications show differentiated development trends based on regional norms. The ISO 3601 standard uses a code format "Section Group Letter + Inner Diameter", e.g., a nominal inner diameter of 7.5 mm is represented as 7.5×1.8 - G - N311. The American standard AS568B uses numbers to identify the 900 series, while the German standard DIN 3771 is marked as Inner Diameter × Cross-Section Diameter plus a quality grade (N/S Grade).

The marking example for the older Chinese National Standard GB 1235-76 was "Nominal Outer Diameter × Cross-Section Diameter + Material" (e.g., 20×2.4 Rubber 1-2), whereas the new national standard GB/T 3452.1-2005 optimizes this to a sequence with cross-section diameter first, followed by inner diameter (e.g., 1.8×4 replaces the old 4×1.8). Key upgrades include supplementing cross-section tolerances like 1.8±0.19 mm, and relaxing the inner diameter tolerance for 710~650 mm to ±0.53 mm. These specifications ensure consistency of O-Ring standard size specifications across various industry applications.

III. Groove Design & Size Matching

O-Ring standard size specifications must be bound to groove design to prevent sealing failure. The groove's inner diameter, outer diameter, and depth must precisely match the O-Ring.

For example, the 4×1.8 specification corresponds to a groove inner diameter of 2.4 mm, outer diameter of 7.6 mm, and depth of 1.28 mm; the groove depth for the 25×3.55 specification is 2.75 mm. The groove width baseline is 1.3 - 1.5 times the cross-section diameter. For dynamic seals, the groove width should be appropriately increased to buffer pressure fluctuations.

IV. Size Classification & Application Selection

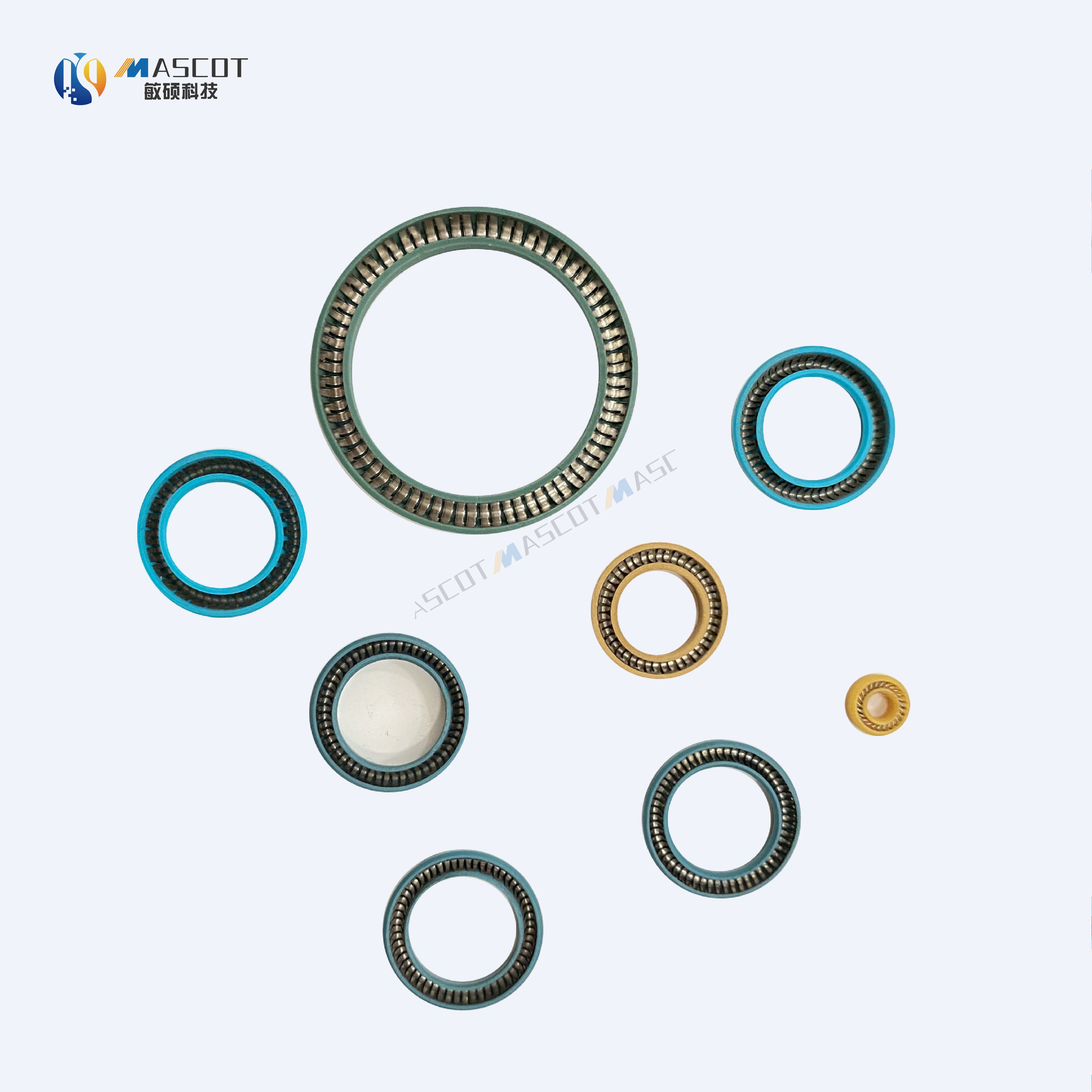

O-Ring standard size specifications are divided into three main series based on inner diameter: Small Size (inner diameter 1.8 - 20 mm, e.g., 8×2.65), Medium Size (inner diameter 21.2 - 50 mm, e.g., 25×2.65), and Large Size (inner diameter 51.5 - 133.4 mm, e.g., 133.4×1.8).

Selection requires comprehensive consideration of working conditions: for hydraulic static seals, O-Rings with a cross-section of 2.65 mm or 3.55 mm are preferred; in high-temperature environments, O-Rings made of PTFE or PEEK materials are more suitable.

About Mascot

Founded in 2005, Mascot has been dedicated to technological innovation for 20 years. The company has obtained certifications including IATF 16949:2016, developed various special sealing formulas, supports custom orders based on provided drawings, and provides tailored solutions. As a pioneer in China's sealing industry, Mascot provides sealing system solutions for domestic and international enterprises. Adhering to the philosophy of "Customer First, Quality Supreme," Mascot continuously tackles technical challenges, contributing to the development of Chinese industry.

Welcome to call 400-008-3858 for inquiries