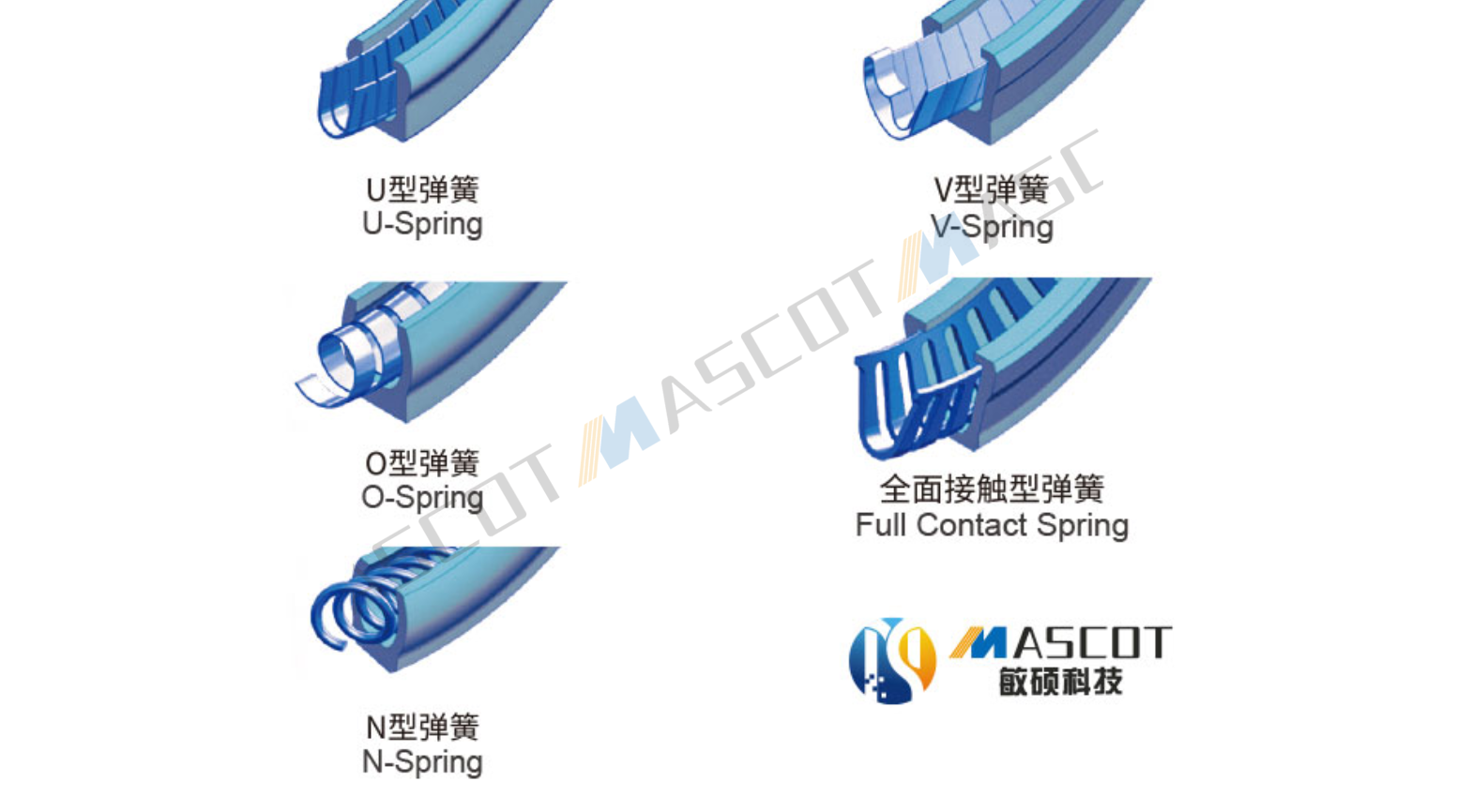

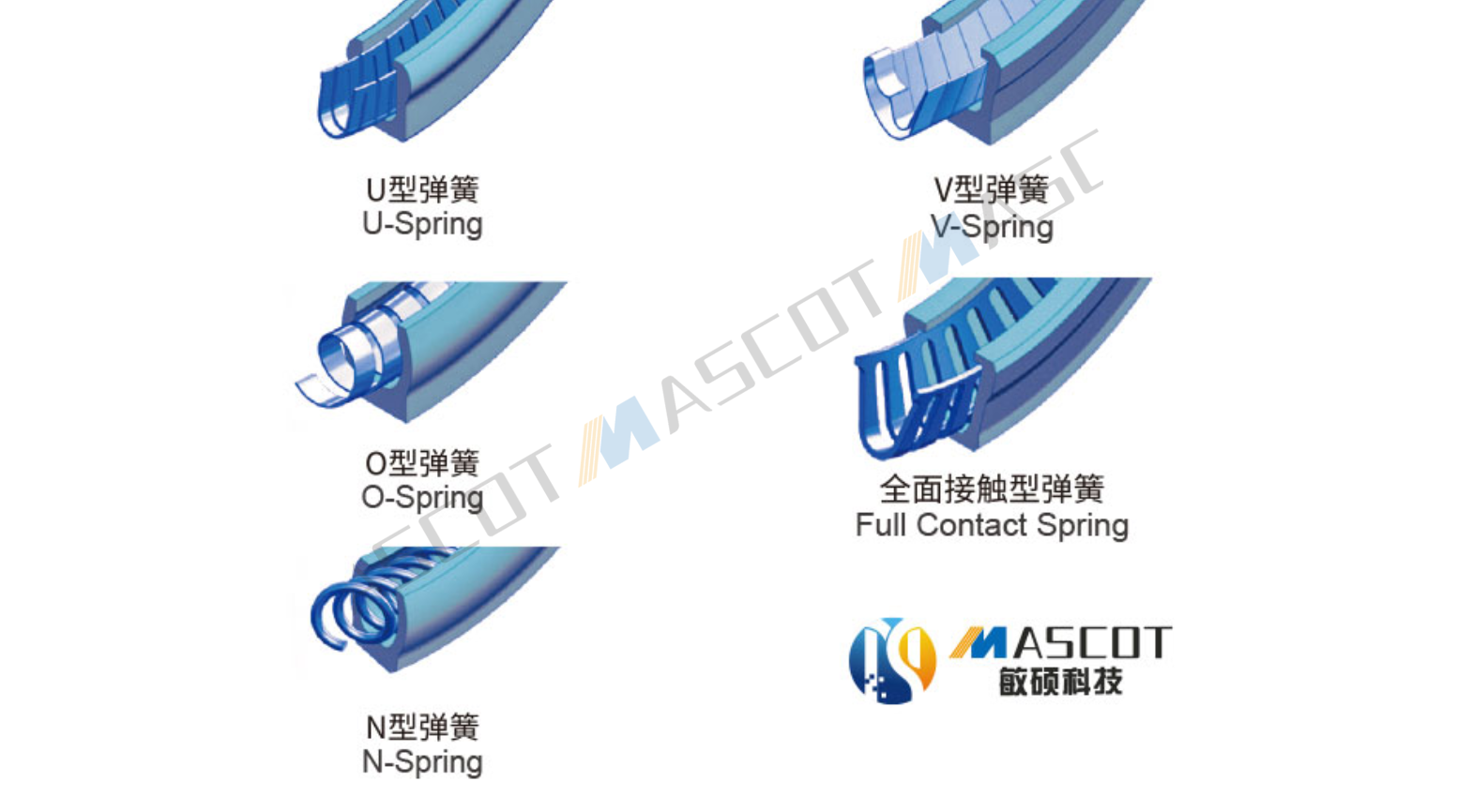

In the field of industrial sealing, spring-energized seals (also known as spring-energized sealing rings) are a viable option for many demanding applications due to their stable pressure resistance, temperature tolerance, and media compatibility. Their sealing performance is closely related to the capabilities of their core component — the spring. Mascot has developed five spring structure types — U-Type, O-Type, V-Type, N-Type, and Full-Contact — to address different sealing scenario requirements, providing adaptable elastic support solutions for industrial sealing.

1. U-Type Spring: A Solution for Compact Spaces

In designs where space is constrained, the U-Type spring features a compact structure. Its open-section design helps save radial space, with a minimum inner diameter of 2mm and wire thickness ranging from 0.1 to 0.8mm. After low-temperature vacuum aging treatment, it demonstrates favorable fatigue resistance, maintaining its elasticity over multiple compression cycles. This structure is suitable for equipment with high space requirements, such as internal sealing in certain medical devices and high-voltage connectors in new energy vehicles.

2. O-Type Spring: A Solution for Annular Sealing Surfaces

For annular surfaces requiring uniform circumferential sealing, the O-Type spring employs a closed-ring structure, which helps achieve relatively even force distribution. It covers a wide range of diameters, and the installation process is relatively straightforward. Large-diameter products utilize segmental winding and welding processes. This structure is commonly used in applications such as petrochemical pipeline flanges, energy storage pressure vessels, and various rotary shaft seals.

3. V-Type Spring: A Solution for High-Pressure Conditions

Under high-pressure working conditions, the V-Type spring exhibits certain pressure-resistant characteristics. Its cross-sectional design helps maintain structural stability in pressurized environments, and its compression performance meets design requirements. This structure is applicable in industrial settings with specific pressure demands, such as downhole tools in oilfields and hydraulic systems in mining machinery.

4. N-Type Spring: A Solution for Pressure-Fluctuating Environments

In environments where working pressure may vary, the dual-peak design of the N-Type spring provides corresponding adaptability. Its structure helps maintain sealing performance during pressure changes and can be compatible with existing seal configurations. It is commonly found in applications with potential pressure fluctuations, such as hydraulic systems in construction machinery and vehicle transmission systems.

5. Full-Contact Spring: A Solution for Irregular Sealing Surfaces

For non-planar sealing interfaces, the Full-Contact spring can be custom-designed according to the actual shape. Its contact form helps improve the sealing condition and performs steadily in dynamic operating conditions. This solution can be used in fields with special sealing surface requirements, such as certain components of aircraft engines, industrial valves, and consumer electronic devices.

As a technical team committed to providing highly adaptable sealing solutions, Mascot consistently focuses on the practical needs of various industrial scenarios. Through continuous technological accumulation and product development, we have established a spring-energized seal product series encompassing U-Type, O-Type, V-Type, N-Type, and Full-Contact springs, aiming to provide reliable support for a wide range of sealing applications. If you have specific operating condition parameters and sealing requirements, please feel free to contact us. Our technical team will assist with spring structure selection and solution design based on your actual situation, providing matched sealing product support for the operation of your equipment.