In the field of industrial sealing, rotary PTFE spring energized seals have become an indispensable key component in numerous industries due to their excellent performance. But do you really have a comprehensive understanding of this type of seal? Its unique design, wide range of applications, and those crucial cold knowledge about groove dimensions that affect performance are all worthy of in-depth exploration.

Rotary PTFE Spring Energized Seals: Unique Design Enables Wide Applications

Rotary PTFE spring energized seals are one-way acting seals specifically designed for rotating shafts, with an extremely wide range of applications. In various hydraulic systems, they can reliably prevent medium leakage and ensure the stable operation of the system; and because the materials used for the seal and spring have excellent compatibility, they also play an important role in the chemical, pharmaceutical, and food industries with high sealing requirements, ensuring the safety and cleanliness of the production process.

The uniqueness of its design lies in the spring-loaded sealing lip. This structure can closely fit the rotating shaft, forming an efficient sealing barrier, fundamentally preventing medium leakage, and providing a solid guarantee for the normal operation of the equipment.

Groove Dimensions: A Key Factor Affecting Performance

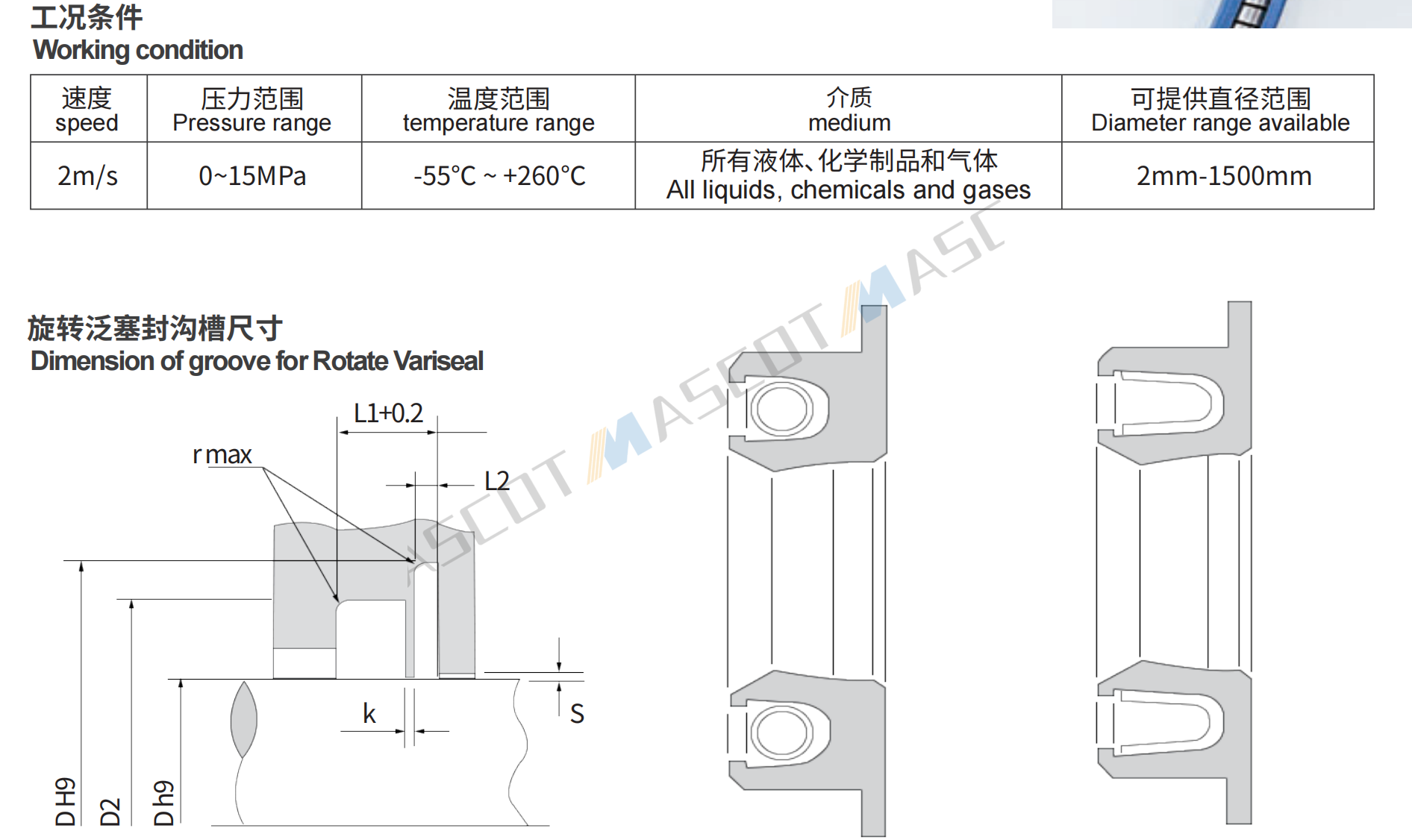

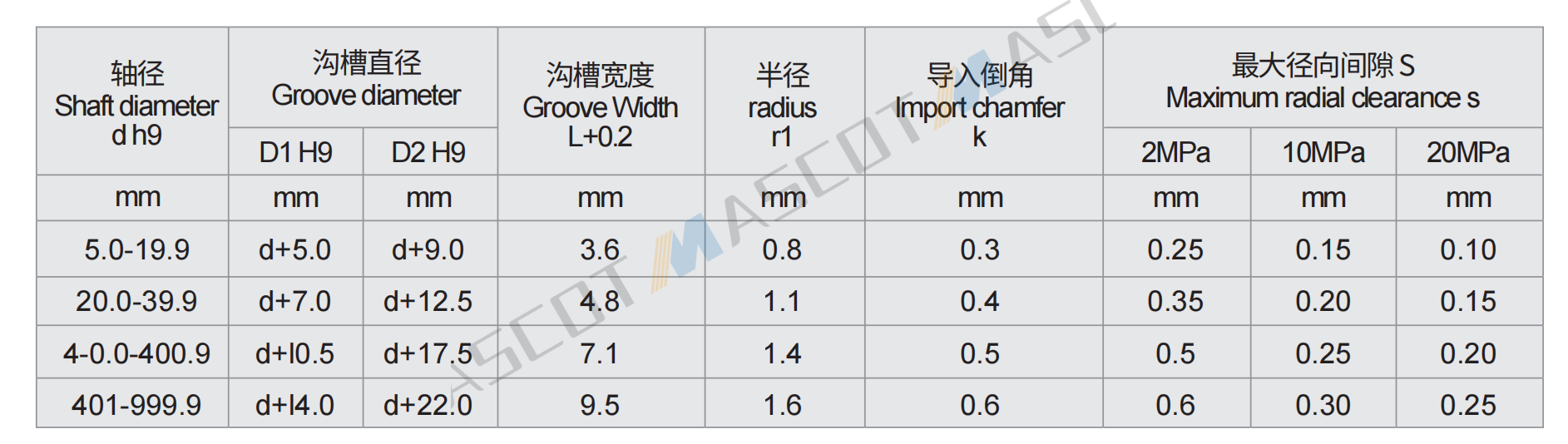

When selecting rotary PTFE spring energized seals, groove dimensions are a crucial factor that cannot be ignored, as they are directly related to the installation effect and performance of the seal. Generally speaking, the depth, width, and angle of the groove must be precisely designed according to the specifications of the seal and specific application scenarios.

Among them, the angle of the groove is one of the key factors affecting the performance of the seal. A reasonable groove angle design can not only make the installation and disassembly of the seal smoother, reduce operation difficulty, but also reduce the friction between the seal and the groove, thereby significantly extending the service life of the seal and saving replacement costs for enterprises.

Mascot: Professional Customization to Ensure Optimal Performance

As a professional seal manufacturer, Mascot has in-depth knowledge and rich practical experience in the groove dimensions of rotary PTFE spring energized seals. We are well aware that the specific needs and application scenarios of different customers vary, so we can provide customized groove dimension design services. Regardless of the specifications of the seal or special application environments, we can accurately grasp them to ensure that the designed groove dimensions enable the seal to exert its best performance and maintain stable and reliable operation.

Choose Mascot, choose professional rotary PTFE spring energized seal solutions, and make your equipment's sealing performance reach a new level. If you have any needs, please feel free to contact us, and we will provide you with comprehensive support and services.