In the operation of aviation hydraulic systems, enduring high-pressure pulses, erosion from aviation hydraulic oil, and wide-temperature environments are common challenges. Polytetrafluoroethylene (PTFE) seals, with their excellent chemical stability, mechanical adaptability, and temperature resistance, have become core components ensuring reliable system operation. Statistics show that over 65% of leakage failures in aviation hydraulic systems stem from insufficient compatibility of sealing materials and inadequate resistance to extreme working conditions. However, PTFE seals can effectively resist corrosion from aviation hydraulic oil (containing complex components such as phosphate esters), operate stably at temperatures ranging from -55℃ to 135℃ and under high pressure of 35MPa, significantly enhancing flight safety redundancy. Based on aviation industry practices, this article systematically analyzes the irreplaceable value of PTFE seals in three dimensions: oil corrosion resistance, temperature change impact resistance, and low friction and wear.

I. Oil Corrosion Resistance: Building a Solid Chemical Protective Barrier

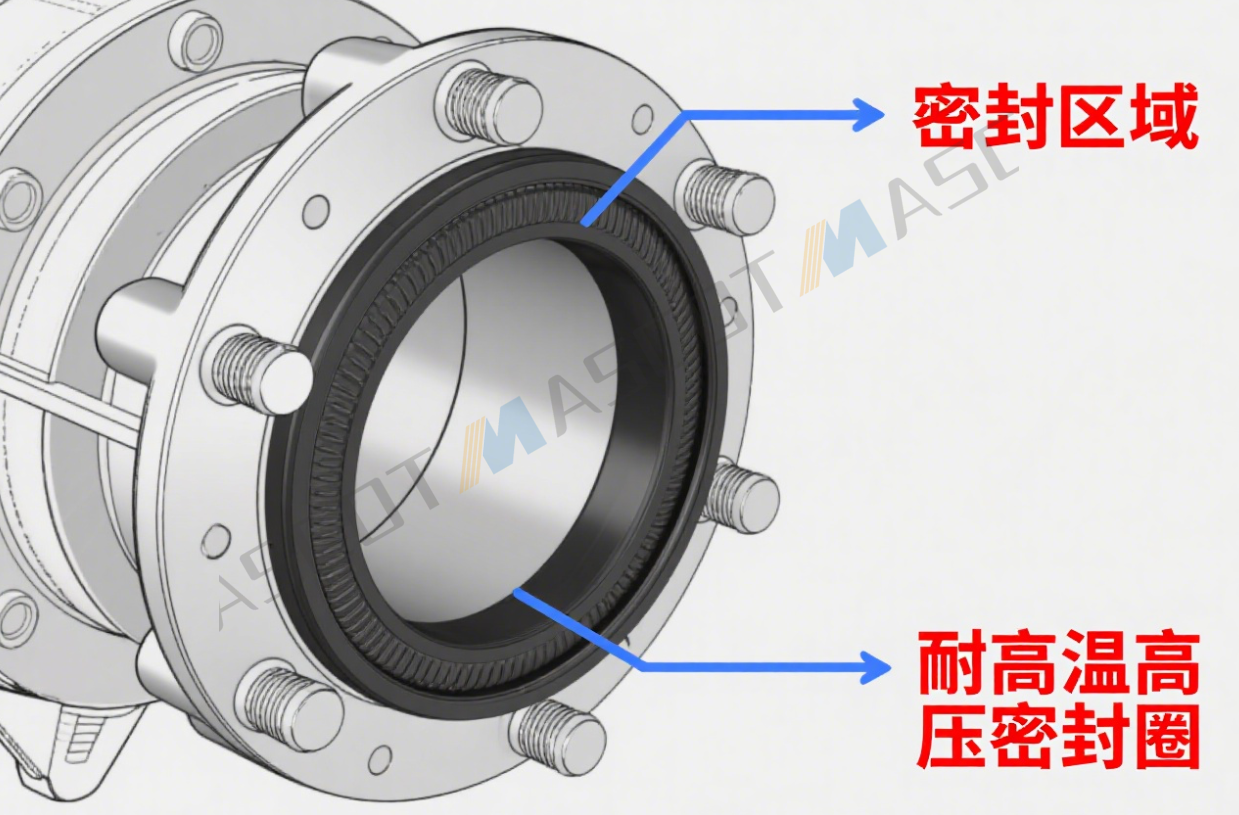

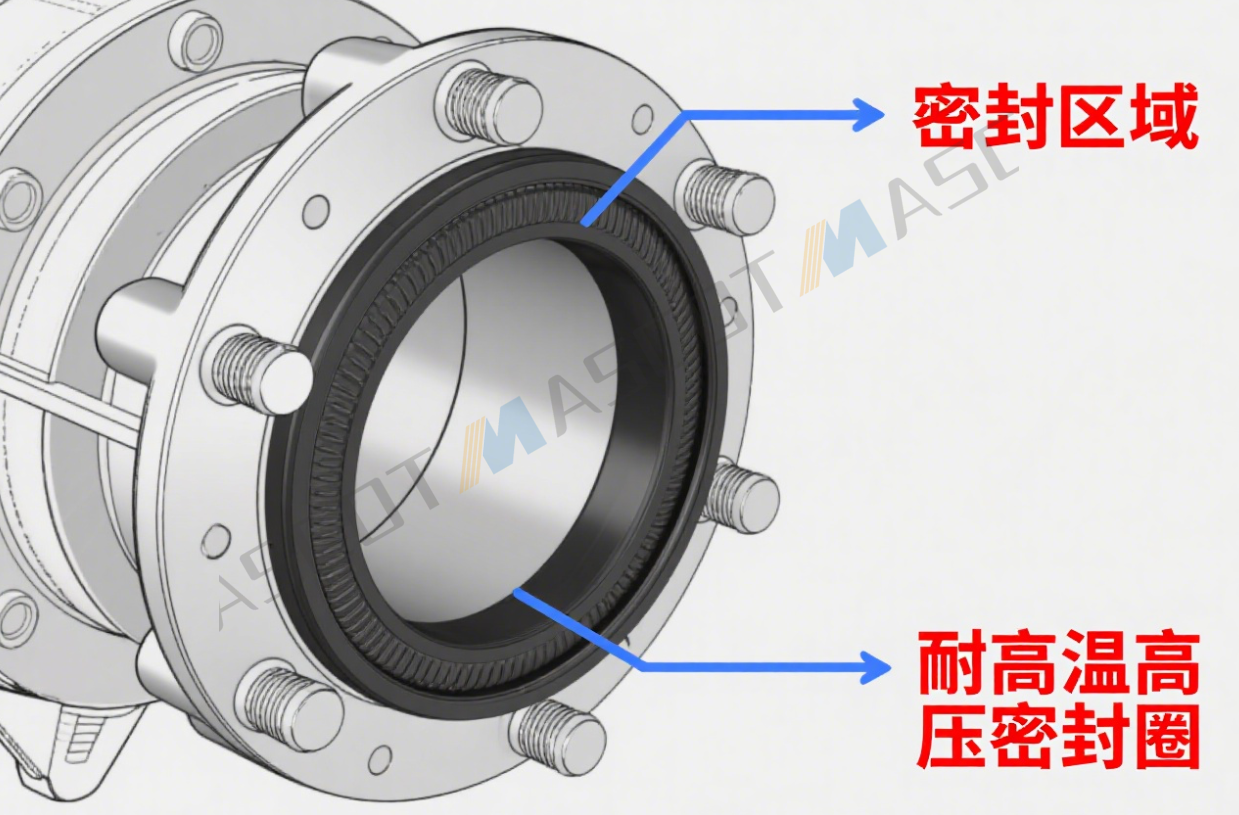

Aviation hydraulic oil contains components such as phosphate esters, which are highly corrosive to sealing materials. In PTFE molecules, the C-F bond energy is high, and fluorine atoms tightly wrap the carbon chain, forming a dense protective layer.

In contrast, nitrile rubber undergoes a volume expansion of over 20% after being immersed in phosphate ester hydraulic oil for 1000 hours; fluororubber cracks when in long-term contact with oil containing chlorine additives. However, PTFE exhibits a mass change rate of less than 0.1% after immersion, with almost no change in mechanical properties. It continuously maintains sealing integrity, preventing hydraulic oil leakage and sudden system pressure drops, thus ensuring the operation of critical flight mechanisms.

II. Resistance to Temperature Change Impact: Stable Performance in Wide-Range Temperature Fluctuations

Aviation hydraulic systems need to adapt to drastic temperature changes from -55℃ to 135℃. PTFE has a glass transition temperature as low as -196℃, with strong molecular chain rigidity, so it does not become brittle in extreme cold. At high temperatures, its structure remains stable, and thermal expansion does not cause excessive sealing gaps or material deformation. This is crucial for ensuring flight safety, as the normal operation of aviation hydraulic systems is directly related to the maneuverability and safety of the aircraft. Whether during takeoff, flight, or landing, PTFE seals can work stably in wide-temperature environments, ensuring no leakage in the hydraulic system and enabling accurate and reliable operation of all critical aircraft mechanisms.

III. Low Friction and Wear: Safeguarding Efficient Operation

Under the high-pressure pulse conditions of aviation hydraulic systems, seals are required to be wear-resistant and have low friction. PTFE has a friction coefficient of 0.04-0.1 and excellent self-lubricating properties, which can effectively reduce friction with the sealing surface in high-pressure pulse environments.

Mascot Environmental Technology (Jiangsu) Co., Ltd. uses imported PTFE materials. The advantages of its seals in low friction and wear provide strong support for the efficient operation of aviation hydraulic systems, enabling them to work stably under extreme working conditions and for the safe flight of aircraft.