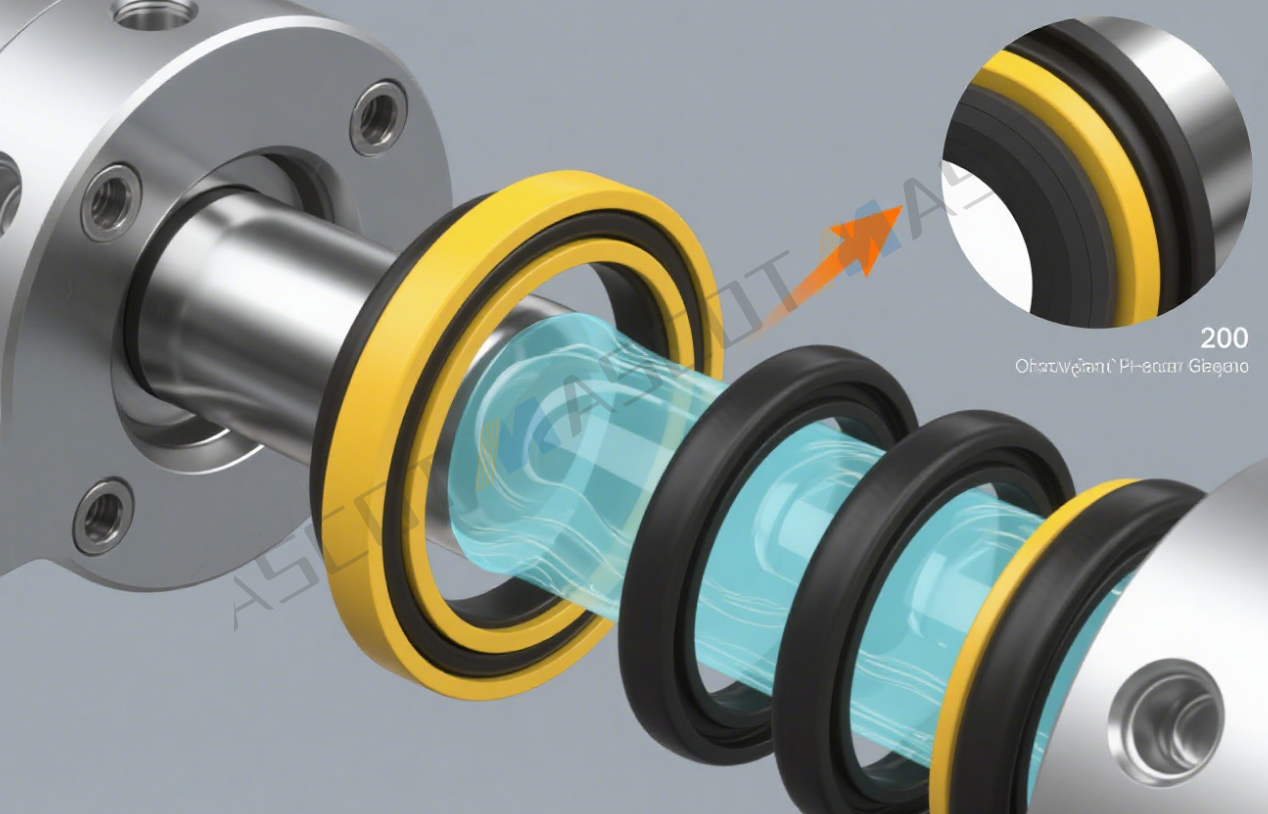

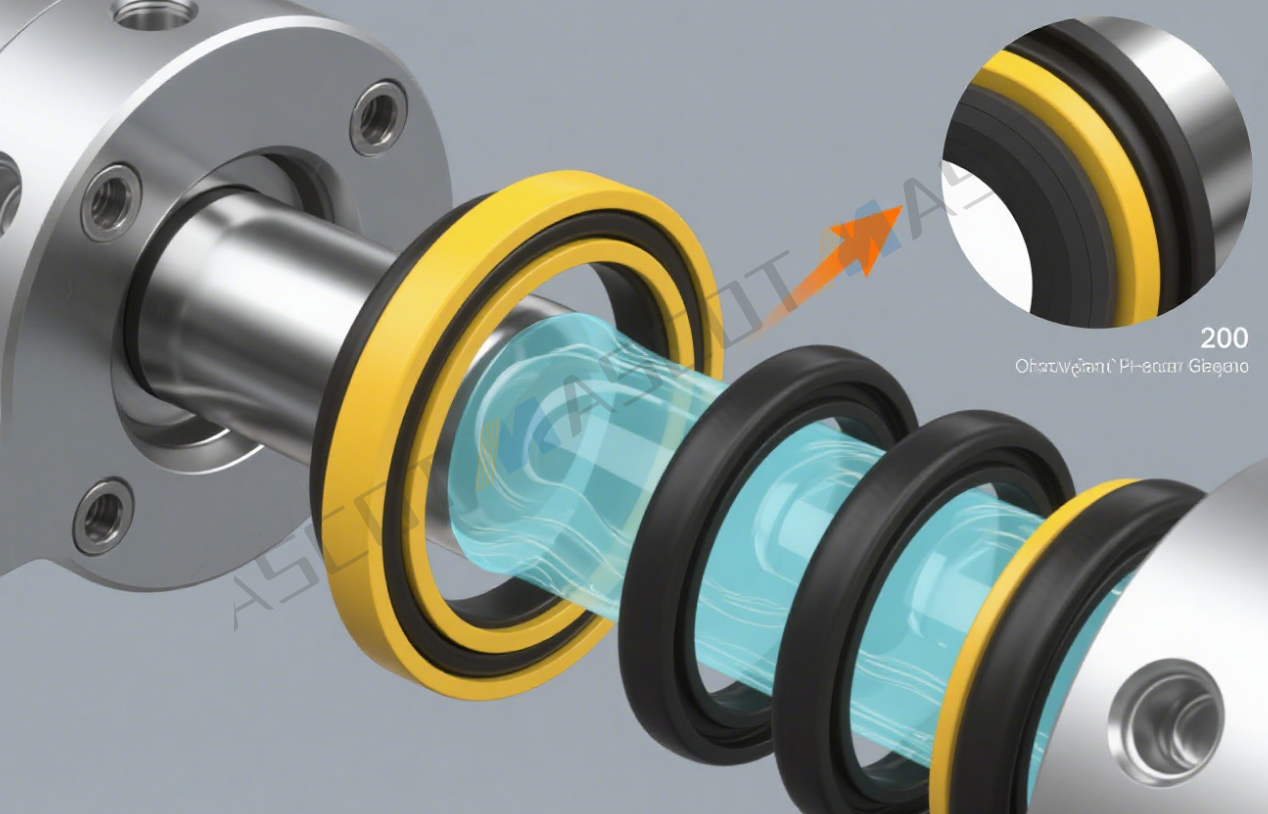

In the electromechanical equipment industry, high-efficiency rotating sealing performance directly impacts equipment reliability, lifespan, and operational efficiency. To address the sealing requirements of high-speed rotation, high pressure, and complex working conditions, Mascot Technology, drawing on years of technical expertise, has launched a high-performance Bore-Mounted Rotary Glyd Ring solution, redefining sealing standards with premium materials and structural design.

Core Advantages of Bore-Mounted Rotary Glyd Rings

Outstanding Pressure & Extrusion Resistance

The Rotary Glyd Rings use reinforced polyurethane (PU) or specialty composite materials, combined with a unique stepped design, to withstand dynamic pressures up to 40 MPa, effectively preventing lip extrusion deformation under high-pressure conditions and significantly improving sealing stability.

Low Friction & Long Service Life

Through optimized sealing lip contact angles and surface treatments (e.g., low-friction coatings), the friction coefficient is reduced by over 30%, lowering startup torque and energy consumption. Suitable for high-frequency rotation applications, these rings offer twice the lifespan of conventional Glyd rings.

Wide Media Compatibility

Compatible with hydraulic oil, lubricants, water-glycol, and other common media. Custom materials are available for high-temperature (-40°C to +120°C) or corrosive (e.g., acid/alkali) environments, meeting diverse needs in mining machinery, injection molding machines, wind power equipment, and more.

After testing the sealing solution, many customers have praised the Bore-Mounted Rotary Glyd Ring solution, seal quality, and service. Mascot Technology has served numerous domestic and international clients, accumulating extensive industry experience to provide precise, efficient sealing solutions tailored to specific sector needs. For more details, please contact Mascot Technology’s customer service!